Add to Cart

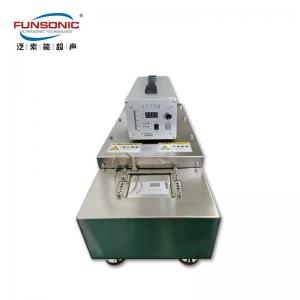

Ultrasonic Immersion Weding Soldering Tin Coating Technology Electronic Manufacturing Industry

Description:

Ultrasonic immersion welding is a method of welding that utilizes ultrasonic technology and is commonly used in the immersion welding process in the electronic manufacturing industry.

The traditional immersion welding method involves immersing the welded component (such as electronic components or connectors) into a preheated solder bath, melting the solder and covering it on the solder pads of the welded component, forming a reliable welding connection. Ultrasonic immersion welding introduces ultrasonic vibration on the basis of traditional immersion welding.

The working principle of ultrasonic immersion welding is that during the welding process, through the action of ultrasonic vibration, the solder in the solder bath quickly wets the solder pads of the welded parts with a small and high-frequency vibration speed, improving the welding quality and reliability.

Parameters:

| Model | FST-2020-GL |

| Name | 20Khz Ultrasonic Dip Soldering Equipment |

| Frequency | 20Khz |

| Power | 1000w |

| Input Voltage | 220V±10%,50/60Hz |

| Working Mode | Intermittent or Continuous working |

| Temperature Range | 200 -400℃ |

| Application | Tin, Indium, Silver, Copper, Nickel, Aluminum Wires. |

Advantages:

1. Improve wettability: Ultrasonic vibration can remove the oxide layer on the surface of solder, enhance the wettability between solder and solder components, and make it easier for solder to cover the solder pad.

2. Uniform coating: Ultrasonic vibration can enable solder to be coated on the welded part at a uniform speed and good fluidity, reducing the uneven distribution of solder and the generation of defects such as bubbles.

3. Reduce oxidation: Ultrasonic vibration can reduce the oxidation reaction between solder and welded parts, reduce oxidation losses during the welding process, and improve welding quality.

Ultrasonic Immersion Weding Soldering Tin Coating Technology Electronic Manufacturing Industry