Ultrasonic Eddy Current Spray Coated Nozzles 110Khz Atomization Perovskite Solar Cells Application

Add to Cart

Ultrasonic Eddy Current Spray Coated Nozzles 110Khz Atomization

Perovskite Solar Cells Application

Description:

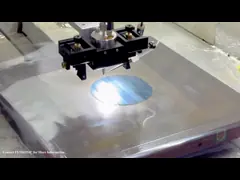

The vortex type ultrasonic atomizing nozzle system uses the unique

cavity design of FUNSONIC and the fast rotating airflow to produce

a wide and stable spray beam. By adjusting the distance between the

atomizing head and the workpiece, the vortex nozzle can produce a

conical spray beam with adjustable diameter.

The principle of vortex ultrasonic atomization nozzle is to inject

a small amount of air or gas into the tail of the ultrasonic

nozzle, and the gas will circulate inside and force the liquid

droplets to diffuse outward. By adjusting the gas flow, liquid flow

and probe amplitude, a wide spray mode can be obtained. This

attachment is very suitable for coating large areas with a small

amount of liquid flow and providing a uniform coating on the

substrate.

The vortex type nozzle utilizes an air shield to generate a wide

patterned "vortex like" dispersion, which is very suitable for

coating flat objects such as PEM (fuel cells) and solar cells.

Compared to other types of nozzles, vortex type nozzles spray more

evenly on curved surfaces.

Parameters:

|

Characteristics and Advantages:

1. High precision droplet control: The vortex type ultrasonic

nozzle provides high-precision droplet control capability. By

adjusting the frequency and amplitude of ultrasonic vibration,

precise adjustment of droplet size can be achieved. This is very

important for applications that require a specific range of droplet

sizes, such as nebulization in the pharmaceutical field.

2. No need to add compressed air: Compared to traditional nozzles,

vortex type ultrasonic nozzles do not require additional compressed

air to generate atomization. This reduces energy consumption and

system complexity, and can also lower operating costs.

3. Low noise operation: Eddy current ultrasonic nozzles typically

operate at lower noise levels. This is very beneficial for

applications that require a quiet operating environment, such as

laboratory research or medical equipment.

4. Corrosion resistance: Eddy current ultrasonic nozzles are

usually made of corrosion-resistant materials to meet the spraying

requirements of various liquids and chemicals. This enables the

nozzle to have good durability and stability in applications with

corrosive liquids.

5. Self cleaning ability: Due to the effect of ultrasonic

vibration, the vortex type ultrasonic nozzle can clean the nozzle

on its own, preventing blockage and accumulation. This helps to

improve the reliability and stability of the nozzle, reducing the

need for maintenance and cleaning.

6. Customizable design: Eddy current ultrasonic nozzles can be

customized according to specific application requirements. The

geometric shape of the nozzle, ultrasonic vibration parameters, and

the design of the eddy current device can all be adjusted according

to specific requirements to meet customer needs.

The development and application of vortex type ultrasonic nozzles

are constantly increasing, with advantages such as high efficiency,

precise control, low energy consumption, and low noise, making them

an important choice for atomization and spraying technology in many

industries and fields. Whether in industrial production, scientific

research, or medical fields, vortex type ultrasonic nozzles provide

high-quality and reliable atomization solutions for many

applications.

Ultrasonic Eddy Current Spray Coated Nozzles 110Khz Atomization

Perovskite Solar Cells Application