Ultrasonic Non Woven Rotary Welding System

Add to Cart

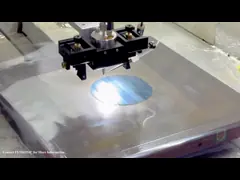

Ultrasonic Non Woven Rotary Welding System

Description:

Ultrasonic sewing machine core is a sewing machine core component based on ultrasonic technology, used to achieve needle free sewing. It is an innovative sewing technology that, compared to traditional needle and thread sewing, does not require the use of needles and threads. Instead, it utilizes the vibration of ultrasonic waves to generate heat energy, laminating materials together to achieve sewing effects.

Principle:

Ultrasonic vibration: The ultrasonic vibrator produces high-frequency ultrasonic vibration.

Thermal energy generation: Ultrasonic vibration can cause frictional heat between materials, causing an increase in surface temperature of the materials.

Pressing and connecting: When the surface temperature of the material reaches the melting point, the material is laminated together with appropriate pressure to melt and bond together.

Parameters:

| Model | FSSW-3508-Ti |

| Name | 35Khz Ultrasonic Rotary Welding Machine |

| Frequency | 35Khz |

| Power | 800w |

| Input Voltage | 220V±10%,50/60Hz |

| Welding Amplitude | 18-28μm |

| Materials of horn | Titanium Alloy or Special Steel |

| Application | Fabric cutting, lace cutting, clothing stitching, gluing, bead inlay |

Features:

1. No needle or thread required: The ultrasonic sewing machine does not require the use of traditional needles and threads, eliminating issues related to threading, thread ends, and needle holes.

2. High speed and efficiency: Ultrasonic sewing can achieve high-speed sewing and improve production efficiency.

3. No need for pre drilling: Ultrasonic vibration can penetrate the material and generate heat energy on the surface in contact, without the need for pre drilling.

4. Beautiful and firm: Ultrasonic sewing can achieve uniform sewing effect, making sewing more beautiful and firm.

Ultrasonic sewing machine cores are widely used in fields such as textiles, clothing, automotive interiors, and household goods, especially in production environments that require high speed and efficiency. It can improve production efficiency, simplify operating procedures, and have good stitching effects.

Ultrasonic Non Woven Rotary Welding System