Product Details

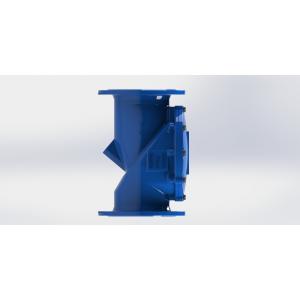

Swing Flex Check Valve For General Water Supply / Sewage Rubber

Coated Wedge

40 degree incline Nylon Reinforcement Disc Swing Flex Check Valve

Ductile Iron EPOXY Coated

Description:

A rubber flapper swing check valve consists of a valve body, a

cover, and a flapper that is connected to a hinge. The disc swings

away from the valve-seat to allow flow in the forward direction,

and returns to valve-seat when upstream flow is stopped, to prevent

backflow. It is under ductile iron construction. Ductile iron

provides greater strength and toughness than conventional gray iron

materials. With ductile iron construction, the body, disc, and disc

arm can safely withstand high stresses and shock loads.

Features:

· Double fl ange design, the disc is composed of DI plate, steel

bar shaft and nylon reinforced fabric.

·The rubber disc is totally encapsulated in EPDM rubber for

superior sealing and corrosion resistance.

·The unrestricted full flow area combined with smooth streamline

contouring allows for passage of large

solids to prevent potential clogging.

·Nylon fabric is inserted into the disc for stengthening the disc

from cracking and breaking during operations.

·Much shorter stroke to minimize water hammer and water slamming.

·All iron parts are coated in fusion bond epoxy resin. Fusion

Bonded Epoxy (FBE) is provided on the interior and exterior of the

valve

·Simple design, top entry cover allows for access for cleaning,

replacement and maintenance easy.

·Meets BS EN 1074-3 and BS EN 558 F/F dimensions.

General Applications:

For general water supply, fire fighting,HVAC/ cooling & sewage

system.

| Size | DN50-DN600 |

| Working Temperature | - 10C- 80C |

| Flange | AISI B16.1 Or PN16 |

| Flow Media | Water and Waste Water |

| Quality System | |

| IQC | Check call incoming parts |

| IPQC | Check the production process is qualified |

| FQC | All valves are pressure tested |

| OQC | Check the valve ourlook and packing |

Test requirement:

•Low pressure test : 0.5 Bar

•Opening pressure : 0.2 Bar

•Seat test : 17.6 Bar

•Body test: 24 Bar

Material:

Company Profile

Alpine Flow Control (SuZhou) Co.,Ltd with major focus in the water

valve design and manufacturing. The Management staff have over 30

years experience in the water valve design and manufacturing,

combined with the high-tech electronics manufacturing experience of

multi-national listed companies. This unique combination of

traditional and high-tech industry management experience and skills

have given us an advantage over the traditional valve manufacturer.

More than 40% of our staff are technical staff with knowledge and

experience in valve and mechanical design/manufacturing...

Proven and supported by on-going quality and reliability test. AFC

has built it’s own in house reliability test laboratory to ensure

that our products not only meet the international quality and

reliability test specification such as the EN-1074-1/2 T-key and

R-key test, but also comply to various international valves

standards and specifications.

We already achieved WRAS certificate in 2011, and obtained FM

approval in early of 2012,

and UL for gate valve. Today, we have got many international famous

certificate for drinking water such as WRAS, NSF, AS, CE on certain

products, and our product range has expended to double eccentric

butterfly valve, rubber disc check valve ,non-slam check valve,

both clean water & sewage water air valve, hydraulic control

valve and penstock and we always focus on water system valves.

In 2018 year, our big plan is developing pressure management valves

which has been proved to be a very helpful tool and economic way to

save the leakage rate with limited investment and get a fast return

in couple months and power savings

In addition, we have a special project team to focus on custom

design and special requirement

Our Mission :

Be the market leader in Water Valve Flow Control

Company culture :

Technology through Innovation

Quality product and service through Quality people

Business growth through Cohesive partnership