Add to Cart

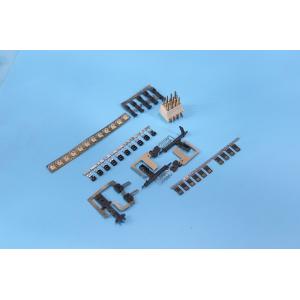

Small electronic parts plastic connector mental terminal injection

mold supplier

Mould Information:

Product Description | Custom plastic injection electronic parts |

Plastic Materials: | PS, ABS, PP, PVC, PMMA, PBT, PC, POM, PA66, PA6, PBT+GF, PC/ABS,

PEEK, HDPE, TPU, PET, PPO,…etc. |

Other materials: | Rubber, Silicone rubber, LSR, Aluminum, Zinc, Copper...Metal…etc. |

Quality: | RoHS and SGS standard |

Feature: | Non-marking and Non-flash |

Size: | According to your 2D, 3D Drawing |

Color, Quantity, Unit price, Tooling cost, Tooling size: | To be discussed |

Mold structure: | In-Mold Decoration, Injection Mould, Plastic Mold, Overmould, 2K

Mould, Die-Casting Mould, Thermoset Mold, Stack Mold,

Interchangeable Mold, Collapsible Core Mold, Die Sets, Compression

Mold, Cold Runner System LSR Mold,…etc. |

Mould Base: | Hasco Standard, European Standard, World Standard |

Mould Base Material: | LKM, FUTA, HASCO, DME,…etc. Or as per Customer's Requirments. |

Surface Finish: | Texture(MT standard), High gloss polishing |

Cavity/Core Steel: | P20, 2311, H13, 2344, Starvax 420, 236, AdC3, S136, 2312, 2379,

2316, 2083, Nak80, 2767 …etc. |

Cavity: | Single Cavity, Muti Cavity, Based on Customer's Requirement. |

Hot/ Cold Runner: | HUSKY, INCOE, YDDO, HASCO, DME, MoldMaster, Masterflow, Mastip,

Taiwan made brand…etc. |

Mould Life: | 1,000 to 1,000,000 Shots. (According to your working environment.) |

Design & Program Softwares: | CAD, CAM, CAE, Pro-E, UG, Soildworks, Moldflow, CATIA….etc. |

Equipment: | High-speed CNC, Standard CNC, EDM, Wire Cutting, WEDM, Grinder,

Plastic Injection Molding Machine for trial out mold from 50-3000T

available. |

Package: | Standard exported Wooden box packed, Fumigation process(upon

required) |

Mold Building Lead Time: | T1, 4-5 weeks, Part measurement report (upon required). |

Export Country: | Europe, Japan, America, Australian, UK, Canada, France, Germany,

Italy…etc. |

Experience: | 11 years of experience in plastic injection mold making and plastic

products produce. |

Annual Production: | 300-500 sets of moulds. |

Our Advantage:

1. Competitive price.

2. Continuance service and support.

3. Diversified rich experienced skilled workers.

4. Custom R&D program coordination.

5. Application expertise.

6. Quality, reliability and long product life.

7. Mature, perfect and excellence but simple design.

After-sales services:

Spare parts offering, like spring, ejector pins…

Mould maintenance as much as possible

Some inserts or plate for cost payment

Mould and plastic part design available

Prototype:CNC,SLC,SLS available

Injection moulding available

FAQ:

1. Why choose us?

Our company has over 10 years’ experience in manufacturing plastic

injection parts, rubber parts, and metal die-casting parts. You can

find too many manufacturers in China. But sometimes, maybe you have

an item, which plastic parts assembled with rubber parts or metal

parts, or plastic injection parts and rubber parts molded with

metal parts. Then our company will be a good choice!

Once you choosing us, I think we will establish a long-term

business relationship and will be friends!

2. What are we specialized in and what’s the main material?

3. What’s our payment term and method?

Tooling(mould): 50% deposit, 50% paid against the approval of

samples;

Samples: less than 10pcs is free;

Products funds: 30% deposit, 70% paid before shipment.

4. What’s the MOQ ( minimum order quantity)?

It’s up to the detailed products. Generally, the total funds should

be more than US$500.

5. What’s the process of deal?

6. What’s the owner of the toolings?

Once customers paid 100% amount of toolings, customers will be the

owner of the toolings. We can not produce products by ourselves to

sell to other customers.