Add to Cart

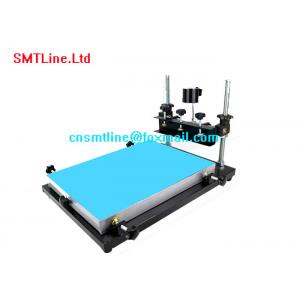

TRY Easy-Manu SMT screen printing machinery printer stencil printer

manual solder paste printer

Quick Detail

SIZE:

20*20CM 24*30CM 30*40CM 40*50CM

Handprint table series

Manual Screen Printing Mach

★ Positioning method: three-side positioning or hole positioning

Mode of orientation: Trilateral Orientate or Hole Orientate.

★ adjustment method: manual fine-tune

Mode of adjustment: manual fine tuning

★ Adjustment direction: X direction, Y direction, Z direction,

height up to 300mm

Orientation of adjustment: X,Y,Z, Max.height:300mm

Features: It is made of imported aluminum alloy and alloy steel.

The parts adopt high-grade electrostatic spray and high-grade

electroplating technology. Accurate positioning, easy operation,

can be freely adjusted before and after the upper and lower left

and right, suitable for machine printing and fingerprint, is the

ideal printing equipment for small and medium-sized electronics

factory and processing plant.

Adopt stainless steel and alloy steel materials, and the components

using top grade electrostatic spray, and high-end electroplating

process. which is suitable for flat topping screen printing,, easy

to operate and accurate positioning, and can be adjusted to up/

down, Left/ right, front/ back.Itis the best choiceforall small and

medium-sized printing factories.

Equipment Model

TX-YT2430

TX-YT3040

TX-YT4060

TX-YT 6080

Table area (mm)

Printing table Size

Max Frame's Size:

240*300mm

300*400mm

400*600mm

600×800mm

Thickness of printing

200 mm

200 mm

200 mm

200 mm

weight:

8KG

12KG

20KG

45KG

Feature

| Product Name: | ySmt Manual Solder Paste Printer |

| Used for: | PCB Screen Printing Stencil Machine |

| Warranty: | 1 Year |

| Shipment | by air |

| Delivery Time: | 1-2Days |

| Our Main Market | Whole of the world |

Application

This equipment is suitable for small and medium batch production.

Specifications: Small 24*32CM Medium 32*44CM Large 45*60CM

1, positioning method: edge positioning

2, adjust the way: manual fine-tune

Adjust the direction: front and rear, left and right, up and down.

3, technical indicators:

Adjustable distance between worktables: ±10mm

Adjustable distance before and after table: 0---30mm

The maximum height of the frame up and down adjustable distance:

120mm

Operating procedures:

1, first use the machine to check whether the four supporting foot

cups are reliable, to ensure that the machine platform is stable

and not shaking; Firstly clear all thimble, positioning seat and

pad on the platform; determine the workpiece or PCB board and

template to be printed. After the preparation work is done, follow

the following steps: 1. PCB positioning: first look at the position

of the PCB and the template, find the most suitable position on the

platform for PCB positioning, it is recommended: use the PCB and

the template after positioning Very few double-sided adhesives →

Place the template in the positioning groove of the wire frame →

Paste the back of the PCB slightly more than the template with

double sided tape → Press down the template afterwards → Install

the aluminum alloy on the platform and the PCB board Pad → adjust

the distance between the template and the pad to the thickness of

the PCB (the PCB and the pad are consistent) to ensure that the PCB

is completely parallel with the pad → remove the previously

attached double-sided adhesive on the PCB → close the pad and the

pad Press firmly to stick the PCB to the pad → Lift the template →

The PCB is separated from the template and stick on the pad on the

platform → Find the positioning pin suitable for the PCB and

install it inside the positioning seat (note that the height of the

pin cannot exceed the PCB thickness )→The positioning seat is

attached to the PCB after the needle is attached and the

positioning is locked. To the platform, positioning base with two

ends → trimming and trimming internet PCB handle grip to lock the

adjustable platform to the optimum position → internet.

2. Printing: Select a suitable length (depending on the printing

width) of the doctor blade during printing, and keep the whole

machine screw tight (special attention to the fixed part of the

template); otherwise, the printing accuracy will be affected. A

printing force in the printing process affects the thickness of the

solder paste. A very skilled and technically savvy operator will

not be inferior to the printer. The operator can directly influence

the quality. The above operation process is the best way discovered

by our company's long-term adjusters and customers and is for

reference only. If there is a better, faster positioning method,

everyone is welcome to share it together, and the use of such a

printing station is extremely useful.

Features

1, can choose the same platform with the printing press, single and

double-sided positioning is convenient and flexible, ensuring

printing accuracy;

2, the printing plate can rotate 45 degrees, and the repeat

accuracy is extremely high, comparable to the machine;

3, The school edition mode adopts the stencil net movement,

combined with the X, Y axis fine-tuning correction of the printing

platform, convenient and quick;

4, The rack is made of thickened Fangtong, with superior material

selection, strong and durable, and the stencil frame adopts spiral

screw up and down 5, adjustable height, which is convenient for

controlling the PCB thickness;

6, according to the customer's different size of the PCB to develop

various sizes of models;