Add to Cart

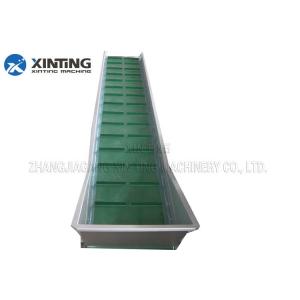

belt conveyor can load plastic ,belt loader with metal detector

The conveyor belt, also known as the conveyor belt, is a rubber and

fiber or metal composite product used for carrying and conveying

materials in a belt conveyor, or a composite of plastic and fabric.

Belt conveyors are widely used in agriculture, industrial and

mining enterprises and transportation industry to transport various

solid block and powder materials or articles, which can be

transported in continuous, high-rate, large-angle, safe operation,

and easy to use. Easy maintenance, low freight, and can shorten the

transport distance, reduce project cost, save manpower and material

resources

There are many kinds of conveyor belts and they are classified

according to their use: general purpose conveyor belts, flame

retardant antistatic conveyor belts, general flame retardant

conveyor belts, heat-resistant conveyor belts,

high-temperature-resistant conveyor belts, acid and alkali conveyor

belts, oil-resistant conveyor belts, and cold-resistant conveyors.

Bands, etc.

According to the structural materials, there are common cotton

canvas conveyor belts, nylon conveyor belts, polyester conveyor

belts, steel cord conveyor belts, PVC core conveyor belts, PVG core

conveyor belts, and steel cable conveyor belts.

According to the product structure, there are: layered conveyor

belts, whole core conveyor belts, steel cord conveyor belts, steel

cable conveyor belts, tubular conveyor belts, pattern conveyor

belts, rib conveyor belts, and sub-conveyor belts.

For the sake of convenience, we generally use a unified

representation method to represent various conveyor belts, and the

representation of various types of conveyor belts.

1. Common expression method for layered conveyor belts (The

standard representation method is different from this, please refer

to the standard GB7984 for details):

Taking NN200 1000×6(6+3) as an example, NN200 represents nylon 200,

1000- represents the width of the tape, 6- represents the number of

nylon layers, and (6+3)-indicates that the upper and lower covers

of the conveyor belt are respectively 6 mm and 3 mm thick.

In general, PVC and PVG flame retardant conveyor belts for coal mines are represented by the strength level and the width of the belt. The intensity level is generally divided into: 4 levels, 5 levels, 6 levels, 7 levels, 8 levels, 9 levels, 10 levels, 11 levels and ** to 16 level belts, respectively corresponding to the intensity: 680S, 800S, 1000S, 1250S , 1**S, 1600S, **0S, 2000S, 2240S, 2500s, 2800S, 3100S and 3**S. The width of the conveyor belt is generally: 500mm, 650mm, 800mm, 1000mm, 1200mm, 1400mm, 1600mm, 2000mm and so on.

China stipulates that all conveyor belt products used in coal mines must be fire-retardant antistatic conveyor belts that comply with relevant standards in China. Now commonly used in coal mine transportation with: PVC flame-retardant anti-static conveyor belt, PVG flame retardant anti-static conveyor belt, flame-retardant anti-static conveyor belt.