Add to Cart

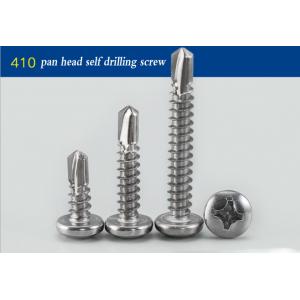

#14 x 1 " Self Drilling Tek Screws, Full Thread, Phillips Drive, Stainless Steel 410 Bright Finish

1. Produc Descriptions:

Pan head self drilling screws is produced strictly according to the DIN7504N standards, Self-drilling screws enable drilling without first creating a pilot hole. These screws are usually used to join materials like sheet metal. Pan head is a low disc with a rounded outer edge that offers a bearing surface.

2. Specifications:

1. Name: DIN7504N pan head self drilling screws, stainless steel pan head self drilling screw

2. Grade: C1018, C1022, SUS201,SUS410,SUS304,SUS316,A2-70,A2-80,A4-80

3. Size: 3.5mmx10mm--6.3x200mm

4. Standard: DIN7504N

5. Certification: ISO9001, SGS, CTI, ROHS

6. Drive: philips, pozi, socket, hex, square, sloted, combined

7. End point: drilling point

8. Packing: bulk packing, small box packing, plastic box + pallet

3. Applications:

Phillips pan head self drilling screws have a sheet metal thread with a self driller cutting (TEK) point to pierce through 20 to 14 gauge metals.

Similar to sheet metal screws, but they have a drill-shaped point to cut through sheet metal or steel which eliminates the need for drilling a pilot hole. These self-drilling screws are designed for use in soft steel or other metals.Self-drilling screw points are numbered from 1 through 5, the larger the number, the thicker metal it can go through without a pilot hole. A 5 point can drill a 0.5 in (13 mm) of steel, for example.

Self-Drilling Screws are also commonly called:

• Tek Screws

• Pro Points

• Self Tapping Screws

• Drill Bit Tip Screws

4. Drawing Technical Data:

| Nominal | A | H | H1 | J | T | M | G | N | Phillips | |||||||

| Size | Head Diameter | Height of Head | Width of Slot | Depth of Slot | Dimensions of Recess | Driver | ||||||||||

| Slotted | Recessed | Diameter | Depth | Width | Size | |||||||||||

| Max. | Min. | Max. | Min. | Max. | Min. | Max. | Min. | Max. | Min. | Max. | Min. | Max. | Min. | |||

| 2 | 0.167 | 0.155 | 0.053 | 0.045 | 0.062 | 0.053 | 0.031 | 0.023 | 0.031 | 0.022 | 0.104 | 0.091 | 0.059 | 0.017 | 1 | |

| 3 | 0.193 | 0.18 | 0.06 | 0.051 | 0.071 | 0.062 | 0.035 | 0.027 | 0.036 | 0.026 | 0.112 | 0.099 | 0.068 | 0.019 | 1 | |

| 4 | 0.219 | 0.205 | 0.068 | 0.058 | 0.08 | 0.07 | 0.039 | 0.031 | 0.04 | 0.03 | 0.122 | 0.109 | 0.078 | 0.019 | 1 | |

| 5 | 0.245 | 0.231 | 0.075 | 0.065 | 0.089 | 0.079 | 0.043 | 0.035 | 0.045 | 0.034 | 0.158 | 0.145 | 0.083 | 0.028 | 2 | |

| 6 | 0.27 | 0.256 | 0.082 | 0.072 | 0.097 | 0.087 | 0.048 | 0.039 | 0.05 | 0.037 | 0.166 | 0.153 | 0.091 | 0.028 | 2 | |

| 7 | 0.296 | 0.281 | 0.089 | 0.079 | 0.106 | 0.096 | 0.048 | 0.039 | 0.054 | 0.041 | 0.176 | 0.163 | 0.1 | 0.029 | 2 | |

| 8 | 0.322 | 0.306 | 0.096 | 0.085 | 0.115 | 0.105 | 0.054 | 0.045 | 0.058 | 0.045 | 0.182 | 0.169 | 0.108 | 0.03 | 2 | |

| 10 | 0.373 | 0.357 | 0.11 | 0.099 | 0.133 | 0.122 | 0.06 | 0.05 | 0.068 | 0.053 | 0.199 | 0.186 | 0.124 | 0.031 | 2 | |

| 12 | 0.425 | 0.407 | 0.125 | 0.112 | 0.151 | 0.139 | 0.067 | 0.056 | 0.077 | 0.061 | 0.259 | 0.246 | 0.141 | 0.034 | 3 | |

| 1/ 4 | 0.492 | 0.473 | 0.144 | 0.13 | 0.175 | 0.162 | 0.075 | 0.064 | 0.087 | 0.07 | 0.281 | 0.268 | 0.161 | 0.036 | 3 | |

| 5/16 | 0.615 | 0.594 | 0.178 | 0.162 | 0.218 | 0.203 | 0.084 | 0.072 | 0.106 | 0.085 | 0.35 | 0.337 | 0.193 | 0.169 | 4 | |

| 3/8 | 0.74 | 0.716 | 0.212 | 0.195 | 0.261 | 0.244 | 0.094 | 0.081 | 0.124 | 0.1 | 0.389 | 0.376 | 0.233 | 0.21 | 4 | |

5. Self-Drilling Screw Troubleshooting Guide

| Split at point (web) | Excessive force (feed) applied while drilling | Reduce application force |

| Outer corners worn or melted | Drill RPM (cutting speed) too high | Use slower motor or partial trigger pull |

| Cutting edges chipping or breaking | Excessive force (feed) applied while drilling | Reduce application force |

| Point melted or diameter significantly reduced | Work material too hard | Confirm work material specs |

| Insufficient chip clearance | ||

| Excessive force (feed) applied while drilling | Choose screw with longer pilot section | |

| Reduce application force | ||

| Screw spins without drilling a hole | Drill motor set on reverse | Check motor direction |

| Work material too hard | Confirm work material specs | |

| Drill point blunted by handling | Inspect unused drill points for possible damage (from handling) |

6. Advantages:

1. Quality control: we make 100% quality test during producing and before shipping

2. Rich experience: we have been export screws for more than 20 years

3. Competitive prices: the better quality, but cheaper prices

4. Timely quotation: send you prices within one day

5. Good services: we supply OEM, ODM,OBM services and best after-sale services

6. Punctual delivery: we can ship every order without delay

7. More pictures:

DIN7505N PAN HEAD SELF DRILLING SCREWS