Add to Cart

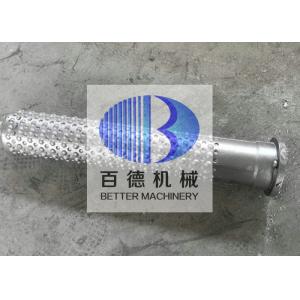

SISIC recuperative burner's silicon carbide heat exchanger of self-recuperative burner

We are a professional team.Our members have many years of silicon

carbide technology and research.

We are a young team.We are full of youthful spirit and innovative

spirit.

We are a dedicated team.We firmly believe that the best brand name

comes from the trust of the customers.Only focus, will make better

products.

We are a dream team.We come from all over the world, as a common

dream: to be a really good silicon carbide production

manufacturers.

Effective team members for the team to show high levels of loyalty

and commitment, intended to allow a group to be successful, we are

willing to do anything."We put the loyalty and dedication, called

consistent commitment.

1) Features:

a) Excellent Thermal Shock Characteristics

b) Corrosion Resistance

c) As Cast Tight Dimensional Tolerances

d) High Creep Resistance

e) Superior Wear Resistance

f) High strength, extreme hardness,wear resistance, high

temperature tolerance, corrosion resistance, oxidation

resistance,thermal shock resistance, high thermal conductivity, low

coefficient of thermal expansion, creep resistance under high

temperature and so on.

2) Benefits:

a) Superior Oxidation Resistance

b) Improved Performance

c) Lowered Cost Burden

d) Longer Life Between Replacement/Rebuilds

e) Allows Lower Weight

f) Very High Thermal Conductivity

Ceramic heat exchanger has the following advantages:

(1) the use of ceramic heat exchanger method is direct, simple, fast, efficient, environmental protection and energy saving.Don't need to be cold and high temperature protection, low maintenance cost, don't need to make any operation ceramic heat exchanger.Suitable for all kinds of environment of industrial kiln of gas waste heat recycling, especially solve the various problem of high temperature industrial kiln waste heat temperature too high can't use;

(2) countries require ceramic heat exchanger temperature 1000 ℃or higher, due to its high temperature resistance, so they can be placed in high temperature area, the higher the temperature, so the heat exchange efficiency, the better, the more energy saving.

(3) high temperature circumstances instead of metal heat exchanger;

(4) solve the problem of chemical industry heat exchange, corrosion resistance;

(5) ceramic heat exchanger strong adaptability, high temperature resistant, corrosion resistant, high temperature and high strength, good oxidation resistance, thermal shock stability, long service life.

In addition, we will work with you to engineer whatever customized solution your process requires