Product Details

Vehicle Door / Window Frame 6463 Aluminum Alloy , T6 Temper Thin

Aluminum Sheet Metal

Alloy: 6463

Temper : T6,T4,T5,T66

6463 aluminium alloy Application:

1.> Band of automobile ,

2.> Decoration adornment inner automobile door frame and

window-frame

3.> Window-frame of auto

6463 aluminium alloy Product character

1. Good processing performance

2. Good use performance

6463 aluminium Chemical Composition Limit

| Cu | Mg | Mn | Fe | Si | Zn | Ti | Cr | Other | Al |

| <0.15 | 0.45~0.9 | <0.05 | <0.5 | 0.2~0.6 | <0.25 | <0.15 | - | - | Remainder |

6463 Aluminum Sheet Mechanical Properties

| Alloy | Temper | Yield Strength (Mpa) | Tensile Strength Rm(Mpa) | Elongation (%) (L0=50 mm) | Hardness(HB) |

| 6463 | T6 | 241 | 214 | ≥15 | ≥74 |

The application of aluminum alloy 6000series in cars

| Typical Alloy | Typical application |

6463 | Structure material,such as the parts of drive system,tie-in

etc;band of automobile ,adornment inner automobile door frame and

window-frame etc,and used as attachment part and other common

aluminum alloy materials. |

FAQ:

Q1: Can you provide Rail Transportation Grade IRIS Certificate?

A: Yes,we can

Q2: How long time get the sample ?

A: One week.

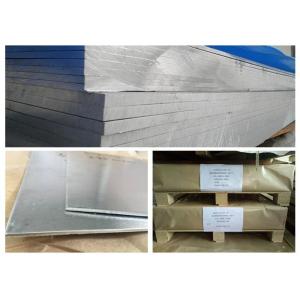

6463 aluminium alloy sheet use and package picture show as below :

Company Profile

Luoyang Tailian New Materials Co., Ltd.

More than 60000 square meters ground area with initial investment

0.28 billion RMB (up to 0.8 billion as planned), Luoyang Tailian

New Materials Co., Ltd. is established in 2016 and located in

Weiliu Road, East Industry Cluster of Yichuan County, Luoyang City,

Henan Province, specializing in manufacturing of commercial

standard aluminium coil, aluminium sheet and further downstream

aluminium foil for electrolytic capacitor (etched foil and formed

foil), aluminium foil tape, honeycomb aluminium foil, decoration

foil and aluminium PS plate.

Currently our plant consists of two aluminium foil production lines

of φ280*φ850*2000mm, a cold-rolling production line (1850mm width),

four 60-ton vacuum annealing furnaces, two 60-ton energy saving

annealing furnaces, two vertical slitting machines, three

horizontal slitting machines (1650mm width), ten etched foil and

formed foil production lines, two production lines of coated foil

for super electrolytic capacitor, standard laboratory and other

supporting facilities.

We are equipped with advanced equipment, complete facilities,

experienced managing, researching and developing team. We have got

multiple national patents for cathode aluminium foil production.

Our products are widely accepted by customers in the market, as

good as Japanese and South Korean products.

In present marketing situation we will keep dedicated to product

quality and marketing ethics to develop along with our customers

and do the best to bring our products and service to a leading

level in the industry.