4 Inch Seamless Ferritic Alloy Steel Pipe ASME / ASTM A335 Standard 13crmo44

Add to Cart

Alloy tube 13crmo44,astm a335 P22 seamless alloy steel pipe ASME

/ASTM A335 standard

We zheheng steel is one of exporter ,manufacturer ,stockist .supply

of ASTM A335 p22 seamless alloy pipe,p22 seamless pipe p22 alloy

pipe, p22 seamless alloy steel pipe,A335 p12 seamless alloy steel

pipe exporter,p22 ss seamless alloy steel pipe supplier ,according

to standard ASME SA210,ASME SA213,ASTM SA335, ASTMA335/A335m,ASTMA213/A213m,DIN

17175 ,and other steel grade

12Cr1MoV,P2(10CrMo910),T91,P91,P9,T9,Cr5Mo,15CrMo,P11,P12,

13CrMo44,25CrMo,30CrMo,40CrMo,12CrMo,X12CrMo91,12Cr2Mo

Referenced Documents

1 ASTM Standards:

A 450/A 450M Specification for General Requirements for Carbon,

Ferritic Alloy, and Austenitic Alloy Steel Tubes

A 999/A 999M Specification for General Requirements for Alloy and

Stainless Steel Pipe 3

E 213 Practice for Ultrasonic Examination of Metal Pipe and Tubing

E 309 Practice for Eddy-Current Examination of Steel Tubular

Products Using Magnetic Saturation E 381 Method of Macroetch

Testing Steel Bars, Billets,

Blooms, and Forgings 5 E 527 Practice for Numbering Metals and

Alloys (UNS) 3

E 570 Practice for Flux Leakage Examination of Ferromag netic Steel

Tubular Products

Product description:

| Item | Cold Rolled / Cold Drawn alloy steel seamless pipe | |

| Standard | JISG3467-88,JISG3458-88,GB3087,GB6479-2000,GB9948-2006, GB5310-95,GB9948-88,ASME SA210,ASME SA213,ASTM SA335, ASTMA335/A335m,ASTMA213/A213m,DIN 17175 | |

| Model No. | 12Cr1MoV,P2(10CrMo910),T91,P91,P9,T9,Cr5Mo,15CrMo,P11,P12, 13CrMo44,25CrMo,30CrMo,40CrMo,12CrMo,X12CrMo91,12Cr2Mo | |

| Description | Surface | black painted,PE coated,galvanized |

| Length | 6m,5.8m,11.8m,12m, or as required | |

| Wall Thickness | 1-120mm | |

| Outer Diameter | 6-1200mm | |

| Trade terms | Payment terms | T/T,L/C,western union |

| Price terms | FOB,CIF,CFR,Ex-work,CNF | |

| Package | Standard export seaworthy package or as required. | |

| Delivery time | Prompt delivery or as the order quantity. | |

Mechanical properties and chemical composition:

| Grade | C | Si | Mn | P | S | Cr | Mo |

| P22 | 0.05-0.15 | Max.0.50 | 0.3-0.6 | Max.0.025 | Max.0.025 | 1.9-2.6 | 0.87-1.13 |

| Mechanical properties | |||||||

| Grade | Yield point (Mpa) | Tensile strength (Mpa) | Elongation(%) | Impact value(J) | |||

| P22 | ≥205 | ≥415 | See table | ≥35 |

Other Documents:

SNT-TC-1A Recommended Practice for Nondestructive Personnel

Qualification and Certification SAE J 1086 Practice for Numbering

Metals and Alloys

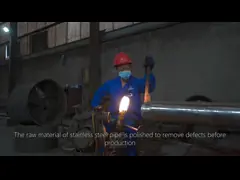

Product show: