Alloy Steel Sheet Metal Laser Cutting Machine 2000W With Fully Automatic Tracking System

Add to Cart

Alloy Steel Sheet Metal Laser Cutting Machine 2000W Full automatic

Tracking System

Overview

FL2000S-1530 Alloy Steel Sheet Metal Laser Cutting Machine has equiped with a

high power laser device and a big sealed working area,which can

protect the worker during cutting operation.

The laser cutter consists of 5 parts ,the machine bed host,

electrical control, water cooling unit, air cooling system and

Exhaust system.

First, the machine bed host is the main part of the whole laser

cutting machine. Cutting function and cutting accuracy of laser

cutting machine are realized by it. It consists of 6 parts ,the

bed, laser source, cantilever, Z axis device, work table, the

auxiliary system (Protective cover, gas and water) and operating

table.

Second, the electrical control system is an important part of ensuring that

all kinds of graphics running tracks, which is composed of the CNC

and the low-voltage electric system.

The CNC machine bed Equipped with BECKOFF system. This system is

based on Windows XP operation system.

Other auxiliary peripheral equipment including large water chiller,

cooling system, exhaust system and power supply

Advantages

1. Great Performance: Identical cutting quality on any cutting

point is realized through fiber transmission.

2. High Efficiency: The rapid cutting speed is two times higher

than that of CO2 laser machine.Its use-cost is low.

3. Low Consumption of Gas: Laser cutting does not make any gas

because of the specific cutting technology on steel plate.

4. Low Consumption of Energy: It is environment-protecting and

energy-saving.Its power consumption is reduced by 20%-30% compared

with that of CO2 laser machine.

5. Maintenance-free: Reflecting lens is not needed for fiber

transmission.Much time is saved when optical path is adjusted.It is

maintenance-free

6. Install Proportional Valve: Use software to change the air and

control the air pressure automatically, no need to change the air

manually, it can save you much time;

7. Stable working table: Use 8mm thick steel side board, around 3.5

tons in weight;

8. Dual drive, aging treatment, stress relief test to ensure long

time fast running without changing shape;

9. Satisfied with flexible processing with small size and intense

structure design.

10. Smaller Focal spot and cutting gap. Much more efficient and

better processing quality.

Parameters

| Laser output power | 1000W/2000W/3000W |

| Laser wavelength | 1070 nm |

| Laser type | Fiber laser souce |

| Max cutting speed | 18m/min |

| Max cutting thickness | 0-18mm according to material |

| Output energy regulating | 10%~100% |

| Input electric power for laser | ≤2KW |

| Type of cooling | Water cooling |

| Drive mode | Imported servo motor |

| Transmission mode | Imported high precision Rack and Pinion |

| Working temperature | 5-45 degrees |

| Continous working time | 24 hours |

| Max-range for cutting | 3000mm×1500 mm/ 2500x1300mm |

| Power supply | 380V/50HZ |

| Service | Oversea service for installation and training |

Cutting parameter

| 300W | 500W | 750W | 1000W | 2000W | |

| Carbon steel | 0-3mm | 0-6mm | 0-8mm | 0-10mm | 0-18mm |

| Stainless steel | 0-2mm | 0-3mm | 0-4mm | 0-5mm | 0-8mm |

| Aluminum alloy | 0-2mm | 0-3mm | 0-4mm |

Application

It is used widly on advertising signs production, sheet metal

structures, production of high and low voltage electrical

cabinet,textile machinery parts,kithen, auto, machinery, metal

technics, saw, electrical parts, glasses, spring, PCB, electical

kettle, medical microelectronics, hardware, tools etc.

Samples

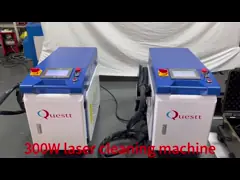

Machine outlook

FAQ

1 Q: What is the warranty of 100W laser rust removal machine?

A: The warranty is 1 year, but we offer whole life after-sale

service.

2 Q: What is the payment terms do you have?

A: T/T, L/C, Westen Union, etc.

3 Q: What is the after-sale service?

A: Engineers can offer oversea services and we can also offer

online service, using online chatting tools like Whatsapp to talk

with customers directly for all questions .

4 Q: How is the quality of the machine?

A: Germany high technoloy with perfect quality.

5 Q: How is the operation of the laser rust removal machine?

A: We offer operation manual and videos, show you how to operate

the machine.

We can also send engineers to your factory for training. Or you can

send worker to gain training in our factory directly.