Add to Cart

1. Description

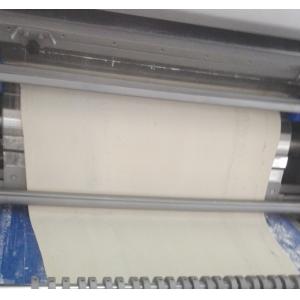

The quality of the final product is to a great extent lie on the quality of dough band , ZMB900 bread production line is configured with sets of multirollers , the bread dough band can be uniformly sheeting .

1 ) The number of multirollers is different in different case .

2 ) The multiroller is made of high quality 304 stainless steel

3 ) Inside the multiroller , there are 12 small rollers and 1 big roller

4 ) The gap can be adjusted manually by a handle aside the device

5 ) All the multirollers are equiped with motors

2. Toast bread line working process

Dough mixing - dough block cut hopper - dough band former - multirollers - stress free roller - dough band dividing - cutter - panning

3. The main techinical datas of this line

| Name | Width | Thickness | Motor |

| Dough extruder | 320 mm | 20 - 40 mm | 0.75 KW |

| Satellite | 360 mm | 3 - 40 mm | 0.75 KW + 0.4 kw + 0.2 kw |

| Calibrator | 380 mm | 3 - 30 mm | 0.75 KW |

| Dividing machine | 560 mm | The space is adjustable a*10mm, 0.75 KW | |

| Cutter | 420 mm | Controlled by servo motor, max speed 200p/min | |

| Panning machine | Tray size 90cm*70cm. Controlled by servo motor, | ||

| The production speed of this line is 2 m / min. Cutting speed is 28 stroke / min, 25 pcs / tray, capacity is 1000kg/h | |||

4. Product strengths

1 ) Top quality

304 stainless steel make it robust structure , world famous components to guarantee a perfect performance, durable , reliable .

2 ) Easy line

The bread production line featured itself as easy line , easy to learn , easy to operate , easy to maintenance and low breakdown .

3 ) Prompt service

Consulting / drawing providing / plant layout design / installation / commissioning / traning / and other technical support .