Add to Cart

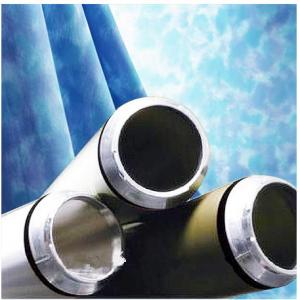

Eco Friendly Rotary Printing Screen Machine Spare Parts High Open Area

Textile Machinery Spare Parts Advantage:

• More tough and tensile, safely operation and multiple use

• orderliness and accurate screen caves, good dye output and osmotic function

• Good symmetrical, good conglutination function of photosensitive medicament

More tough and tensile

Higher strength

Orderliness and accurate screen caves

Symmetrical character

Quality conformity

Safely operation and long-term use

Longer life screen

Good dye output and osmotic function

Good Conglutination function of photosensitive medicament

Symmetrical color and beautiful pattern Perimeter accurte

Product Description:

This product is for new type rotary printing machine. After install endring on two ends and engraved designs on it, we can put the rotary screen on machine. Suitable for print cotton, silk, polyester, wall paper and etc.

Our raw material of nickel is high purity and with less sulfur. Match it with high quality pure additives. Our products has unparalleled excellence performance. Printing ink penetration uniform, Photo emulsion and Sensitizer adhesion is strong bonding, high toughness, high elasticity, good thickness and uniform open area.

What is rotary screen printing

the web travels at a consistent speed between the screen and a steel or rubber impression roller immediately below the screen. (The impression roller serves the same function as the press bed on a flatbed press.) As the web passes through the rotary unit, the screen spins at a rate that identically matches the speed of substrate movement.Rotary screen printing is so named because it uses a cylindrical screen that rotates in a fixed position rather than a flat screen that is raised and lowered over the same print location. Rotary presses place the squeegee within the screen. These machines are designed for roll-to-roll (web) printing on flexible materials ranging from narrow web films to wide-format roll textiles.In rotary printing,

Specification:

| Mesh | Thickness(μm) | Open area | Hole diameter |

| 80 | 115-120 | 18 | 132 |

| 100 | 105-110 | 16 | 108 |

| 125 | 100-105 | 15 | 79 |

REPEAT(mm) 640, 819, 914,1018

LENGTH(mm) 1410-3500

ED=Extra thickness

Delivery time: within 15 to 25 days

Package:plywood cases or as you required

Buyers show: