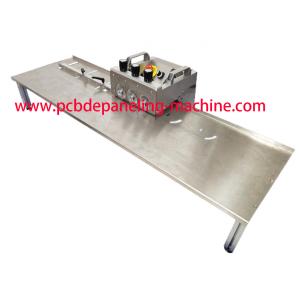

Adjustable White PCB V Grooving Machine Foot Switch Working With Circular Knife

Add to Cart

Adjustable White PCB V Grooving Machine Foot Switch Working With

Circular Knife

CAB PCB Depanelizer MAESTRO 4M YES-6 PCB Separator Technical

Parameters:

1. Three pairs of precision beveled cutting blades can ensure the

board does not bend, or deform

2. Guide can be adjusted vertically to suit differenct LED boards

3. Depth between upper circular blades can be precisely adjusted to

reduce stress on score-line edge and blade wear

4. Upper and lower circular blades can be resharpened

5. 2.4M stainless steel platform is standard; optional lengths

avaiable

6. Two working mode: automatic or foot switch

YES-6 PCB Depaneling Machine Specification:

| PCB separator YES-6 size: | 770mm X 510mm X 450mm |

| Minimize Speed: | 100/200/300/500mm/s(adjustable) |

| Minimize thickness: | 0.3-3.5mm |

| Material of blades | high speed steel |

| Max.PCB separating length | unlimit |

| PCB separating thickness | 0.3-3.5mm |

| Voltage and Power | 110V/220V -- 10W |

| PCB Depanelizer YES-6 weight | 47KG |

| Packing size | 390*460*390mm |

Why Clients Buy Our PCB Separator Model YES-6

1. Currently, it is the only machine that can guarantee the

aluminum plate without deformation after cutting .

2. With unique cutting method, the circuit board is cut by six

blades. It is a group composed of one upper and one lower blade,

and is also a cutting unit.

There are A, B, C, three groups. The whole cutting process is

divided into three stages from group A blade which cut 10% board

then to the group B blade knife cut through groove cutting by group

A to complete another 40% .the last 50% is cut by group C blade and

finishing.

because each cutting volume is small, the stress produced during

the cutting progress declined by more than 50% compared with the

traditional cut off at a time.

Thus the edge of the board and its surface are very smooth without

warping .

3. Because of the multiple cutting, cutting process is very smooth

and greatly improves the capability of position of V-CUT groove

.Even if with shallow slot V-CUT groove the board won't jump out of

blade, avoiding adverse.

4. Because cutting force of the blade is small. The wheel disc with

SKH high precision steel material which is imported from the Japan.

durability of the blade greatly improved , and the lifetime can be

one year or more when cutting the aluminum board.

5. All the cutting blades are calibrated by Excitation

double-frequency laser interference measurement instrument. Ensure

that the latter knife can accurately continue to cut in the slots

which already cut by the former knife. The jitter of knife point is

less than 0.02mm. Ensure perfect cutting quality.

6. Can be mounted stainless steel platform with laser calibration

positioning function

7. Can be adjusted the above and below round knife

precisely,Circular knife can turn mill reoccupy many times, the

shape of cutter can be customized.

8. X, Y axis can free adjustment and make the cutting accuracy to

the highest.

Our YES-6 Pre Scored PCB Separator Application

LED Panel,Fiber Board,Aluminium Plate,Aluminium Substrate,Copper

Substrate FR4,Glass Fiber Board

Customers FAQ About PCB Separator YES-6:

1. Q:Do you have any certification for this machine?

A:YES,We have CE ISO FCC ROHS etc.

2. Q:What is warranty of the machine?

A:1 year.

3. Q:How do you pack the machine?

A:We fix the machine on the plywood base with screws to ensure safe

transportation.

4. Q:What is life time of machine blades?

A:About 6-12 months.

5. Q:What is material of blades?

A:Japan high speed steel SKH-9

6. Q:Can the blades be sharpened?

A:Yes, they could be re-sharpened for 2-3 times.

7. Q:How do you offer oversea service?

A:We could send engineer to do installation and training for client

if needs.

8. Q:Can we see your machine in our country?

A:Yes, we would like to offer contact details of our clients who

are using our machines.