Product Details

6 Axis Robot Arm System Automatic Robot Laser Metal Fiber Laser

Cutting Machine For Production Line

Description:

Fully automated

Intelligent positioning processing

Assembly line customization

Feature:

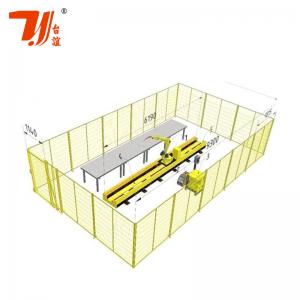

The welding robot adopts a double-station working platform, which

can save the time of installing product fixtures, improve

production efficiency, and realize automatic and intelligent

operation. The welding robot is equipped with a unique swinging

welding head, and the laser is collimated into parallel light by a

collimator, which is focused on the workpiece for welding. In

addition, it can also be equipped with a simple universal

instrument to perform flexible transmission welding of parts that

cannot be touched by large molds, making the operation more

flexible. The welding robot has fast running speed, high repeat

positioning accuracy, few consumables and low operating cost, and

is suitable for large-format space welding.

| Product Name | Automatic Robot Arm Laser Welding Machine |

| Laser Power | 1000W 1500W 2000W 3000W 4000W 6000W optional |

| Laser Source | Raycus IPG JPT MAX optional |

| Robot Arm | Yaskawa ABB KUKA |

| Laser Wavelength | 1070nm |

| Pulse Width | 0.5-15ms |

| Pulse Frequency | ≤100Hz |

| Spot adjusting range | 0.1-3mm |

| Repeating precision | ±0.01mm |

| Cooling System | Water Cooling |

| Voltage | 380V/3-Phase/50Hz/40A/60A |

Advantage:

◆Fine beam quality, Fast welding speed, Beautiful welding effect.

◆High photoelectric conversion efficiency, low energy consumption,

easy maintenance, saving a lot of processing costs

◆It can work 24hours continuously and meet mass production

| Tig Welders | Laser Welders |

| Heat input | Very high heat | Very low calories |

| Deformation | Easy to deform | No deformation |

| Welding spot | Large welding spot | Fine welding spot, adjustable spot |

| Exterior | Unsightly, need polishing | Smooth and beautiful, no need to sand |

| Perforation | Easy to pierce | Not easy to perforate, can be controlled |

| Protective gas | Need argon | Need argon |

| Precision | general | Precision |

| Processing time | Long time | Short time |

| Safety | Ultraviolet light, radiation | Radiation-free |

Application Industries:

It is used for precision metal welding processing, such as welding

of hardware appliances, kitchen and bathroom industries (faucets

and round pipes, kitchenware sheet metal parts, washing machine

inner cylinders, etc.), and precision hardware welding of

electronic industry (mobile phones, tablets, automobiles, etc.). It

can meet the welding of a variety of metals, alloys, steel, Kovar

and other materials of the same kind, as well as dissimilar

materials such as copper-nickel, nickel-titanium, copper-titanium,

titanium-molybdenum, brass-copper, low-carbon steel-copper, etc.

Welding between metals.

Company Profile

Dongguan Taiyi Laser Technology Company Limited was founded in 2001

. We have an outstanding

technical team with 24 years of manufacturing experience. It is a

high-tech comprehensive laser

machinery and equipment manufacturer in laser industry,

Specializing on the teaching ,researching,

development,production and sales.

We have established 3 standardized Intelligent equipment

manufacturing factories,Which are

respectively located in Dongguan Guangdong, Huanggan Hubei and

Gujarat India. Our product

includes laser marking machine ,laser welding machine,laser cutting

machine , laser cleaning

machines, laser cladding machine,and Non-standard customized laser

equipment.

Our after service network has already covered more than 100

countires

For better service from pre-sales and after-sales, Taiyi has set up

offices in China and overseas.

East China (Kunshan) Office, South China (Dongguan factory), West

(Chongqing), Central China

(Hubei base)

Service Stations are also available Overseas: Thailand, Turkey,

India, Iran, Switzerland,

Poland, South Korea, Egypt, Vietnam.

Welcome to join Taiyi family, in making contributions to the world.