Add to Cart

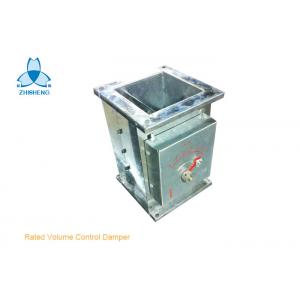

Constant Volume Control Damper

Constant Volume Control damper is installed into the dust to control the airflow of HVAC system or center air conditioning,

Constant air volume valve is a mechanical self-powered device suitable for ventilation and air conditioning systems that require constant air volume. The constant air volume control does not require external power. It relies on the airflow force in the air duct to position the control valve so that the air flow is maintained at a preset flow rate over the entire pressure differential range.

Application:

At present, in China, air-conditioners for fan coils and fresh air

systems are still relatively common, especially in hotel rooms, and

most offices and office buildings use this method. The usual

practice is to install fresh air units on each floor, install new

air ducts in the walkways, and access dozens of branch pipes from

the main pipe to each room.

Taking hotel rooms as an example, the fresh air volume in each room is generally 100 m3/h. How to achieve the same amount of air flow in each branch? In general, designers often add an air volume control valve to the fresh air branch pipe. It is expected that the air volume distribution will be completed through the late debugging method. As the new air system is generally a long trunk pipe and the branch pipe is short, the adjustment of the air volume control valve is neither intuitive, nor is the adjustment accuracy ideal.

Besides, the fresh air volume per room is only 100 m3/h, and the air volume is very small. It cannot be completed. The construction unit can only measure the total air supply volume of the new air duct to ensure that the air supply ducts have a sense of wind. In order to ensure that the fresh air volume sent by each room can reach the design value, there is no need for the construction unit to balance one room and one room. We only need to add a fixed air volume valve to each fresh air branch pipe, and the above problems will be solved.

People who live and work in high-rise buildings often worry about the lack of fresh air, and designers often feel aggrieved. Because from the drawing point of view, the value of the new air volume standard is not low, but we often overlook a problem, how to ensure the actual effect from the design point of view, and the constant air volume valve application in the fresh air system is a powerful measure.

Constant voume control damper classification:

One type is to sense the air flow through the air duct through the

silicone airbag in the balancer, and realize constant air volume

according to different static pressure automatic contraction and

expansion. When the air static pressure at the inlet and outlet is

minimum, the airbag is in a contracted state. When the static

pressure at the air inlet and outlet increases, the airbag begins

to inflate, thereby reducing the space around the airbag. Keep the

flow constant over a range of wind pressures.

The other type is a mechanical self-energizing device that relies

on the airflow pressure in the air duct to position the control

valve so that the air flow is maintained at a predetermined flow

rate within a certain pressure differential range. It requires no

external power and can be added to the electric actuator to change

the flow setting through the remote control signal.

Features:

The constant air volume valve is an automatic mechanical mechanism

that does not require external power, and an electric actuator can

be added to change the flow setting through a remote control

signal. Constant air flow valve can be used in the sending and

exhaust systems. The working temperature is generally 10~50°C, and

the pressure difference range is 50~1000Pa. That is, at least 50Pa

pressure difference is applied after the valve before the valve,

otherwise the fixed air flow valve cannot work. This should be

taken into account because the wind pressure values of the fresh

air system of the new air system are generally not large. The fixed

air volume valve is not limited by the position when it is

installed, but the valve plate shaft should be guaranteed to be

horizontal. Generally, a straight inlet duct with 1.5 times the

length of the valve and a straight outlet duct with 0.5 times the

distance are required.

Constant air volume valve control accuracy, there is an external

pointer display flow scale, adjustment accuracy of about ± 4%,

flow-restricting mechanism without maintenance, to support the

system, fixed air volume valve rectangular, circular, insulation,

silencer type can be selected. Just as the balance valve is more

and more adopted by the designers in the air-conditioning water

system, the constant-flow valve will be widely used in the delivery

and exhaust systems because of its precise and adjustable

characteristics.

Purification system application:

Maintaining the positive pressure value of a clean room in a

purified air-conditioning system is of utmost importance. In

addition to setting the air flow valve in the exhaust or exhaust

system, the positive pressure value in the clean room can be

effectively ensured.

During the operation of the clean operating room, the positive pressure of the operating room needs to be maintained during and when the operation is not performed. When the operation is performed, the amount of fresh air is the amount of fresh air required for positive pressure plus the amount of fresh air required by the person. When the operation is not performed, the fresh air volume is only guaranteed to be positive pressure.

The required amount of fresh air, so the need for a double fixed

air volume valve on the new air duct.