Add to Cart

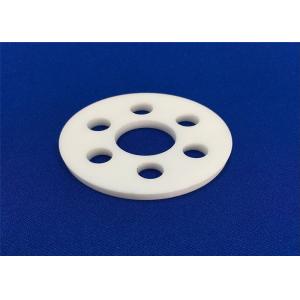

High Heat Resistance Refractory Mullite Zirconia Ceramic Mullite Disc

| Features | Unit | 95% alumina ceramics | 99.5% alumina ceramics | Zirconia ceramics |

| Density | G/cm3 | 3.65 | 3.85 | 6.05 |

| Hardness | Gpa | 12 | 14 | 89 |

| Bending strength | Mpa | 310 | 340 | 1000 |

| Compressive strength | Mpa | 2500 | 3000 | 3500 |

| Highest application temperature | °C | 1200 | 1900 | 2300 |

| Insulation breakdown strength | KV/mm | 16 | 17 | 10 |

zppd_Company_Profile-_Dongguan_Mingrui_Ceramic_1-a...

Feature:

1). low thermal expansion

2). large specific heat capacity

3). high specific surface area

4). low pressure drop

5). small thermal resistance

6). good thermal conductivity

7). good heat-shock resisting ability

Applicatiom:

1) Electric appliance industry

2) Automotive industry

3) Mechanical industry

4) Engineer industry

Alumina ceramic is the most mature of the engineering ceramics,

offering excellent electrical insulation properties together with

high hardness and good wear resistance, but relatively low strength

and fracture toughness. Alumina ceramic is generally white but may

also be pink or ivory. The color is derived from either the

sintering additives or impurities in the raw materials.

More Photos

Delivery:

Custom OEM will be shipped within 15 days after determining the

parameters

The samples will be shipped within 3 days

Quick Delivery Via Fedex,DHL,UPS,TNT Etc.

Support customer to designate shipping company

For more informations (the price,delivery time,moq etc)about the

ceramic plates, please contact us or email:admin@cerampart.com

CEO: Admin deng

Dongguan Mingrui Ceramic Tech. Co. Ltd.

Add: No.21 Chuangxing Rd., 2nd Industrial Zone of Shangsha,

Chang'an town, Dongguan city, Guangdong, China 523867

Email: admin@cerampart.com

FAQ

1. Monthly Capacity: 50,000-60,000 pcs;

2. Material: OEM or as per your suggestion;

3. Lead time: about 7-20 days, pls confirm the quantities required;

4. Incoterm: FOB, CFR, CIF;

5. Delivery Cost: It is determinated by the destination port;

6. Payment Term: PayPal; T/T; L/C.

7. Shipment: by sea, by air, by courier, by post, etc.