Product Details

CEMENTING PLUGS

NON-ROTATIONAL CEMENTING PLUG, CEMENTING TOOLS, CASING BUOYANCY

SYSTEM PART, TOP OR BOTTOM , ANTI ROTATION

Cementing plugs are used to remove the mud during cementing

operations.

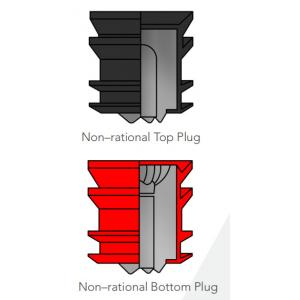

Top cementing plugs and bottom cementing plugs are used in the

cementing process. The top and bottom

cementing plus general have different colors (bottom plugs are red

and top plugs are black) in

production for easy usage in operation.

The top cementing plug has a solid body that provides positive

indication of contact with

cementing floating collar and bottom plug through an increase in

pump pressure.

The bottom cementing plug with a hollow body is installed ahead of

the cement slurry to

minimize contamination by fluids inside the casing prior to

cementing.

ADVANTAGES AND MAIN FEATURES

Non-rotating cementing plugs are designed to decrease the drill out

times. Reinforced locking teeth are

built into the plugs, which lock together between the plug and the

float equipment to eliminate rotation

of the plug during drill out. The top cementing plug are latched to

the anti-rotational float collar.

Performance features

› Non-rotational.

› Decrease drill out time.

› PDC drillable.

Options

› Available in sizes from 4-1/2" to 20".

› Available in NR, SBR, NBR and HNBR grades.

| Casig size inch | Casing weight range | O.D. of rubber cup | Working Temperature | Working pressure mpa | burst pressure mpa | hardness | | 4-1/2. | 14.14-17.26 kg/m | 9.5-11.6 lb/ft | 110mm | 4.331inch | (-30℃-150℃) | ≥15mpa | 1-2mpa | 75-95 | | 5 | 17.11-35.86 kg/m | 11.5-24.1 lb/ft | 122mm | 2.803inch | (-30℃-150℃) | ≥15mpa | 1-2mpa | 75-95 | | 5-1/2. | 20.83-39.88 | 14-26.8 | 135 | 5.315 | (-30℃-150℃) | ≥15mpa | 1-2mpa | 75-95 | | 7 | 25.3-56.55 | 17-28 | 170 | 6.693 | (-30℃-150℃) | ≥15mpa | 1-2mpa | 75-95 | | 7-5/8. | 35.72-63.69 | 24-42.8 | 185 | 7.283 | (-30℃-150℃) | ≥15mpa | 1-2mpa | 75-95 | | 9-5/8. | 53.57-79.62 | 36-53.5 | 235 | 9.252 | (-30℃-150℃) | ≥15mpa | 1-2mpa | 75-95 | | 10-3/4. | 60.27-97.77 | 40.5-65.7 | 260 | 10.236 | (-30℃-150℃) | ≥15mpa | 1-2mpa | 75-95 | | 13-3/8. | 71.43-107.15 | 48-72 | 333 | 13.110 | (-30℃-150℃) | ≥15mpa | 1-2mpa | 75-95 | | 20 | 139.89-197.93 | 94-133 | 498 | 19.606 | (-30℃-150℃) | ≥15mpa | 1-2mpa | 75-95 |

|

Company Profile

SWS offers a range of premium API casing accessories and OCTG to

meet the challenging demands of oilfield and E&P companys

operatiing

world widely.

To meet these demands, sws has established a manufacturing facilitu

of 78000sq ft. This facility has modern CNC maching, fabrication

and

procssing equipment, testing and inspection facilities, together

with raw material and production storage.

To satisfy our customer’s expections, sws offers advanced

production facility, complete and systematic production, as well as

groups of

management, design and manufacturing.

SWS's main facility is located in a major industrial area, with

convenient transportation and science industry around there.

The demands of customer can be met rapidly anf concisely with the

competitive advantage of technology, talent, raw material, together

with

geography and transportation.

SWS has partners all over the world to support our clients on

global supply and support in anytime.

Qualification obtained:

sws is committed to provide competitively advanced technical

facility that has been designed, manufactured and tested to get the

approval of

industry standard API, along with international systematic

standards( API Q1, 14001, 18001)