Add to Cart

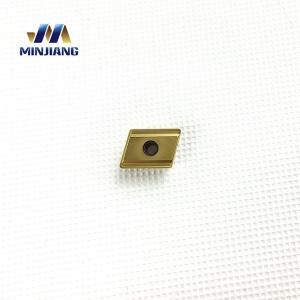

Turning Insert Carbide Manufacturer Tungsten Carbide Insert Cutting Tool With High Hardness

Tungsten Carbide CNC Cutting Tools are renowned as one of the most versatile and valuable equipment options in the realm of CNC machining. Crafted from a combination of robust and resilient tungsten carbide material and a precision-cutting edge, these tools possess the unique ability to effectively shape and manipulate a wide range of materials with exceptional accuracy and precision. Whether it's delicate alloys or tougher substances like stainless steel and aluminum, Tungsten Carbide CNC Cutting Tools effortlessly cut through them, allowing for the creation of complex shapes with remarkably tight tolerances. Moreover, these tools exhibit exceptional resistance to heat, enabling them to withstand high temperatures commonly encountered in high-speed machining processes. Undoubtedly, Tungsten Carbide CNC Cutting Tools hold an indispensable role in any CNC machining operation, providing a dependable and efficient means to produce top-quality parts and components.

Specifiction

| Product Name | Tungsten Carbide CNC Cutting Tools |

| Brand | Minjiang/HL |

| Model | N220928-1103-OM-12IG |

| Coating | PVD/CVD |

| Material | 100% Virgin |

| Grade | MC115/MC118/MC118X/MC335/MC335X |

| Workpiece | Steel/Stainless steel/Alloy steel/Cast iron |

| HRA | HRA 89-93 |

| MOQ | 10 pcs |

Optional Material

| Grade | Properties | Application |

| YG3X | Fine particle alloy with good wear resistance and poor impact toughness. | Finishing of cast iron, nonferrous metals, finishing of alloy steel, hardened steel, tungsten and molybdenum materials |

| YG6X | Fine-grained alloy with good wear resistance and impact toughness. | Semi-finishing and finishing of cast iron, chilled cast iron, alloy cast iron, heat-resistant steel and alloy steel. |

| YG6 | Good wear resistance and impact resistance. | Rough and semi-finishing of cast iron, non-ferrous metals and alloys, and non-metals. |

| YG8 | Higher strength, better impact resistance, poor wear resistance. | Rough machining of cast iron, non-ferrous metals and alloys, interrupted cutting is possible |

| YT30 | Good red hardness and wear resistance, but low strength, not impact resistant, prone to welding and grinding cracks. | Finishing of carbon steel and alloy steel during continuous cutting. |

| YT15 | Good wear resistance and red hardness, but poor impact resistance. | Semi-finishing and finishing of carbon steel and alloy steel during continuous cutting. |

| YT14 | Higher strength and impact toughness, but lower wear resistance and red hardness than YT15. | Roughing, semi-finishing and finishing of carbon steel and alloy steel during continuous cutting. |

| YT5 | Good strength and impact toughness, not easy to chip, but poor wear resistance. | Rough machining of carbon steel and alloy steel during continuous cutting, and can be used for continuous cutting. |

| YG6A | Fine-grained alloy with good wear resistance and strength. | Semi-finishing and finishing of hard cast iron, ductile iron, non-ferrous metals and alloys, high manganese steel, alloy steel, and hardened steel. |

| YG8A | Medium-grained alloy with good strength and poor red hardness. | Rough and semi-finishing of hard cast iron, ductile iron, white iron, non-ferrous metals, alloys and stainless steel. |

| YW1 | Good red hardness, wear resistance, impact resistance and versatility. | Semi-finishing and finishing of stainless steel, heat-resistant steel, high manganese steel and other difficult-to-process materials. |

| YW2 | Poor red hardness and wear resistance, but high strength and impact resistance. | Semi-finishing and finishing of stainless steel, heat-resistant steel, high manganese steel and other difficult-to-process materials. |

Application fields

Supply At Source

Quality: By purchasing products directly from the source factory, customers can be assured of the highest quality standards. Since the products come directly from the production source, there is a reduced likelihood of any compromises in terms of quality. This direct connection ensures that customers receive products that meet or exceed their expectations.

Price: Cutting out the middleman in the supply chain eliminates additional costs and markups, resulting in a more affordable price for customers. By directly dealing with the factory, customers can enjoy competitive pricing as there are no intermediary expenses involved. This cost reduction provides customers with better value for their money.

Timeliness: When buying from the source factory, customers can expect timely delivery without unnecessary delays. Direct communication and coordination with the factory facilitate smoother logistics and efficient order fulfillment. By streamlining the supply chain, customers can have peace of mind knowing that their products will be delivered within the agreed-upon timeframe.

Customization: Dealing directly with the factory allows customers to tailor their orders and personalize products according to their specific requirements. With direct communication channels, customers can collaborate with the factory to customize features, sizes, colors, or any other aspects of the products. This level of customization ensures that customers receive precisely what they need, enhancing their overall satisfaction.

Relationship: Building a relationship directly with the factory establishes a foundation for better customer service. Customers can establish direct lines of communication with the manufacturer, fostering trust, understanding, and effective problem-solving. This direct relationship allows for a more personalized customer experience, as the factory can gain insights into the customer's preferences, feedback, and future needs, leading to improved customer satisfaction and long-term loyalty.

FAQ

1. Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. Or it is 20-35 days if the goods are not in stock, it is according to quantity.

2. Q: Is the price competitive?

A: Yes, we offer reliable products at good prices.

3. Q: Are the products high quality?

A: Yes. The raw material will be tested before bulk production, and we will check the physical properties, shape, and tolerance for ensuring qualified products before shipping.