Add to Cart

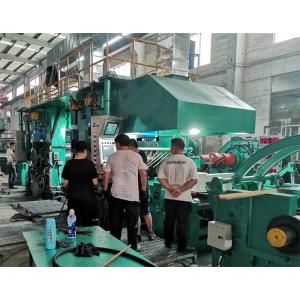

Cold Rolled Steel Strip Rolling Mill Line Reversible or Tandem

Cold rolled steel strip made from hot rolled steel coils by cold

rolling mill, Strip cold rolling is carried out at (or near) the

room temperature, the metal remains below its recrystallization

temperature,and the metal plastic deformation occurs, with strength

of the metals increases around 20% due to strain hardening, and

surface finish of the cold rolled steel increases and higher

dimensional accuracy is achieved. Then allows to meet forming and

bending operations as well as to get good surface finish of highly

engineering steel strips. besides cold rolling process, it also

needs:

We design, make and supply Steel Coil Sheet Cold Rolling Mill,

Reversible or Tandem, different customers from different countries

and regions require different configuration and process cold

rolling mills to cater their local steel sheet market, the rolling

capacity(rolling force, rolling speed, power consumption, etc.)

differ with the market change, so each cold rolling mill should be

designed accordingly.

Carbon steel sheets are most common metal sheet, most of carbon

steel sheets are low carbon steel (mild steel), medium and high

carbon steel sheets are high quality high tensile steel, we make

carbon steel sheet cold rolling machines tailored to corresponding

materials.

The cold rolling mills we mostly supply are carbon steel sheet cold

mills. With productivity improving and steel sheet demand increase,

the carbon steel cold mills are becoming higher speed, higher

precision, lower consumption and lower maintenance cost. Our

company always work with market, know well cold mill technology

development and customer anticipation.

We make each mill customized, after knowing customer requirements:

As per customer requirements, budget and preference, we specify the

detailed specification of proper cold mill, 4high or 6high, tandem

or reversible, and suggest customer machine configuration level and

spares preparation. Customer is a part of our design, he will see

his cold mill is what he hopes.

4Hi Mill Specification:

| Model | strip width | entry gauge | finished gauge | transmission | Rolling force | rolling speed(m/s) mechanic AGC | |

| Ф140/450x450 | 250-350 | 1-2 | 0.2-0.6 | work roll | 300T | 1-3 | 4-6 |

| Ф175/450x450 | 250-350 | 2-3 | 0.3-1.0 | backup roll | 300T | 1.5-4 | 4-8 |

| Ф140/500x500 | 300-400 | 1-2 | 0.2-0.6 | work roll | 400T | 1-3 | 4-6 |

| Ф180/500x500 | 300-400 | 2-3 | 0.3-1.0 | backup roll | 400T | 1.5-4 | 4-8 |

| Ф140/520x550 | 360-450 | 1-2 | 0.2-0.6 | work roll | 500T | 1-3 | 4-6 |

| Ф180/520x550 | 360-450 | 2-3 | 0.3-1.0 | backup roll | 500T | 1.5-4 | 4-8 |

| Ф165/600x650 | 450-580 | 1-2.5 | 0.2-0.6 | work roll | 600T | 1-3 | 4-6 |

| Ф200/600x650 | 450-580 | 2-4 | 0.3-1.5 | backup roll | 600T | 1.5-4 | 4-8 |

| Ф175/650x750 | 550-680 | 1-2.5 | 0.2-0.6 | work roll | 700T | 1-3 | 4-8 |

| Ф220/650x750 | 550-680 | 2-4 | 0.3-1.5 | backup roll | 700T | 1.5-4 | 4-10 |

| Ф180/750x900 | 600-800 | 1-2.75 | 0.2-0.6 | work roll | 800T | 1-3 | 4-8 |

| Ф230/750x900 | 600-800 | 2-4 | 0.3-1.5 | backup roll | 800T | 1.5-4 | 4-10 |

6 Hi Mill Specification:

| Model | strip width | entry gauge | finished gauge | transmission | Rolling force | rolling speed(m/s) | |

| Ф150/175/460x450 | 250-350 | 1.0-2.5 | 0.15-1.2 | work roller | 280T | - | - |

| Ф150/175/500x500 | 300-400 | 1.0-2.5 | 0.15-1.5 | work roller | 350T | - | - |

| Ф165/200/630x650 | 400-550 | 1.0-3.5 | 0.18-2.0 | work roller | 500T | - | - |

| Ф165/250/680x800 | 550-700 | 1.0-3.5 | 0.2-2.0 | work roller | 550T | 3.5 | 4-8 |

| Ф170/300/800x900 | 600-800 | 2-4 | 0.2-2.0 | work roller | 650T | 3.5 | 4-10 |

| Ф300/370/950x1050 | 650-950 | 2-4 | 0.2-2.0 | work roller | 1000T | - | 4-10 |

| Ф130/370/1050 x 1250 | 700-1100 | 2.0-4.0 | 0.2-2.0 | work roller | 1200T | - | 8-12 |

| Ф400/450/1250 x 1450 | 800-1250 | 2.0-4.0 | 0.2-2.0 | work roller | 1500T | - | 8-16 |