Add to Cart

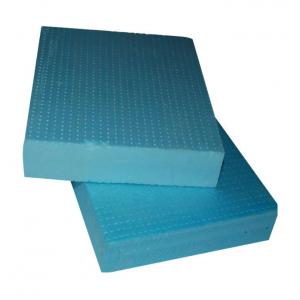

Flame Retardant Grade B1 Extruded Polystyrene Xps Extruded Board Floor Heating Insulation

item | value |

Warranty | 5 years |

After-sale Service | Online technical support, Other |

Project Solution Capability | total solution for projects, Others |

Application | Office Building |

Design Style | Industrial |

Place of Origin | Chongqing, China |

Brand Name | Haike |

Panel Material | Nonmetal |

Product name | XPS Extruded Board |

Material | Polystyrene, XPS Wall Insulation |

Color | Blue, Blue Flame Retardant Foam Board |

Density | 27-35Kg/m3 |

Length | 1.2/2.4m |

Width | 0.6m |

Size | 10-80mm |

Flame Retardant | B1 B2 |

Compressive Strength | 250kpa |

Water Vapor Permeability | ≤3.5ng/(m.spa) |

Products Description

The xps insulation board is made of polystyrene resin as raw material plus other raw and auxiliary materials and polymers. It is a rigid foamed plastic board manufactured by heating and mixing while injecting a catalyst, and then extrusion molding. Its scientific name is extruded for heat insulation. Plastic polystyrene foam (XPS for short), XPS has a perfect closed-cell honeycomb structure.

Products feature

Heat insulation

It has the characteristics of high thermal resistance, low

linearity, and low expansion ratio. The closed cell rate of its

structure has reached more than 99%. Practice has proved that the

thermal insulation effect of 20mm thick XPS extruded insulation

board is equivalent to that of 50mm thick expanded polystyrene,

120mm Thick cement perlite. Therefore, this material is the best

choice for building insulation.

High strength compression

Due to the special structure of the XPS board, its compressive

strength is extremely high. According to different types and

thicknesses of XPS, its compressive strength can reach more than

150-500Kpa.

Hydrophobic, moisture-proof

Water absorption is an important parameter to measure insulation

materials. Since the molecular structure of polystyrene itself does

not absorb water, the molecular structure of the board is stable

and has no gaps, which solves the problems of water leakage,

penetration, frosting, and condensation of other materials.

Lightweight and easy to use

The xps insulation board is easy to cut and transport, and it is

not easy to be damaged and easy to install.

Good stability and corrosion resistance

Even if the XPS extruded insulation board is used for 30 to 40

years, it can still maintain excellent performance, and it will not

decompose or mildew, and there will be no volatilization of toxic

substances.

Product environmental protection

The chemical properties of the XPS board are stable after being

tested by the relevant state departments.

Application

1. Building roof insulation, steel structure roof, building wall

insulation, building ground moisturizing, square ground, ground

frost heave control, central air conditioning ventilation ducts,

etc.

2. The ground moisture-proof insulation layer is widely used in the

bottom moisture-proof of various buildings, under the roadbed of

roads, railways, and airport runways in alpine regions.

3. Interior decoration, advertising board, widely used in interior

decoration, suspended ceiling, sound insulation wall, sandwich door

filling material.