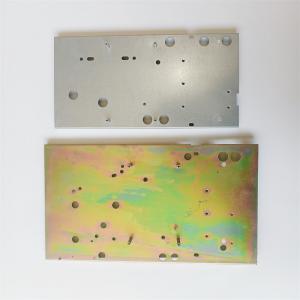

CNC Punching Custom Metal Box Fabrication , Precision Sheet Metal Bending

Add to Cart

Sheet Metal Fabrication Bending Stamping Works Box Enclosure Processing Parts

Sheet metal processing is called sheet metal fabrication. Specifically, for example, the use of plates to make chimneys, iron drums, fuel tanks and oil cans, ventilation pipes, elbows and heads, rounded places, funnel-shaped, etc., the main processes include shearing, bending, bending, bending, welding, riveting, etc. Some knowledge of geometry. Sheet metal parts are thin-plate hardware parts, that is, parts that can be processed by means of stamping, bending, stretching, etc. A general definition is a part with a constant thickness during processing. Correspondingly, castings, forgings, machined parts, etc.

Material selection

The materials commonly used in sheet metal processing are

cold-rolled sheet (SPCC), hot-rolled sheet (SHCC), galvanized sheet

(SECC, SGCC), copper (CU) brass, red copper, beryllium copper,

aluminum sheet (6061, 5052, 1010, 1060, 6063, duralumin, etc.),

stainless steel (mirror surface, brushed surface, matte surface),

according to the different functions of the product, the selection

of materials is different, and it is generally necessary to

consider the use and cost of the product.

Product parameters:

Material available | Stainless steel 201/304/316, sheet metal ( SPCC, SECC), aluminum

alloy etc. | |||

Fabrication service | Laser Cutting ,Stamping, Punching , Bending, turning ,Welding,

machining, surface treatment, and other General Fabrication Service | |||

Surface Treatment | Powder coating, Zinc plating, chrome plating, hot-dip, Silkscreen,

polishing and so on. | |||