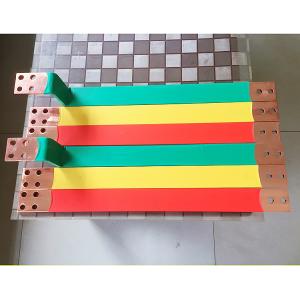

Anti Corrosion Copper Flat Busbar , Stainless Steel Busbar With Pressure Riveting

Add to Cart

Power Distribution Cabinet Copper Busbar With Pressure Riveting

What are the characteristics of copper busbar?

Copper busbars have good electrical conductivity, low resistivity,

high mechanical strength, and good anti-corrosion performance, but

they are expensive.

What are the characteristics of aluminum busbar?

The resistivity of aluminum busbar is slightly larger than that of

copper, its electrical conductivity is inferior to that of copper,

its mechanical strength is smaller than that of copper, and it is

easy to corrode and oxidize, but it is cheap and light in weight.

What are the characteristics of steel busbar?

The steel busbar has poor electrical conductivity, high

resistivity, the highest mechanical strength, and the worst

anti-corrosion performance, but the price is cheap.

What are they suitable for?

Copper has the advantages of high electrical conductivity, high

mechanical strength, corrosion resistance, etc., but it has many

important uses in industry, and its output is small and expensive,

so it is mainly used in corrosion-prone areas (such as near

chemical plants or coastal areas, etc.).

The conductivity of aluminum is second only to that of copper, and it is light in weight, cheap in price and high in output. It is widely used in indoor and outdoor power distribution devices.

Steel has high mechanical strength, but poor electrical conductivity, and is only used in high-voltage and small-capacity circuits (such as voltage transformer circuits, small-capacity factory use, and the high-voltage side of transformers used), low-voltage circuits with operating currents not greater than 200A, DC circuits and grounding devices. in the loop.

Product parameters

Material | Non-ferrous alloy material like carbon steel,stainless

steel,galvanized steel,aluminum,copper,brass,etc |

Surface Finish | All kinds of surface treatment are available like chrome

plating,zinc plating,nick plating,powder coating,e-coating,dip coating,mirror polishing,etc. |

Application | Electronic/Appliance/Auto/Industrial equipment metal stamping

hardware parts |

Processing | Our process includes tooling fabrication,stamping,deep

drawing,punching, spinning,laser cutting,bending,seamless welding,machining and assembly |

Quality Control | Liability System and Periodical QC on line every hour |

Main Market | USA/Germany/Canada/Italy/United

Kingdom/Australia/Pakistan/French,etc |