Add to Cart

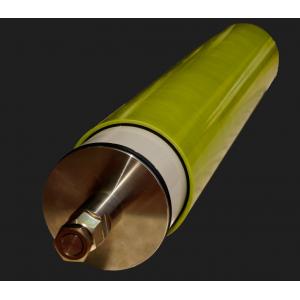

DTRO Disc Tube RO Membrane Filter Module for High Salts Water Treatment

Disc tube membrane technology is DT membrane technology, which is

divided into DTRO (disc tube reverse osmosis), DTNF (disc tube

nanofiltration), DTUF (disc tube type nanofiltration) There are

three categories of tubular ultrafiltration, which are membrane

modules specially used to treat high-concentration sewage. The core

technology is the disc tube membrane column. put the diaphragm.It

is stacked with the hydraulic deflector, fixed with the central

pull rod and the end plate, and then placed in the

pressure-resistant casing to form a membrane column.

DT series products overcome the shortcomings of common reverse

osmosis systems that are easy to block when treating leachate,

making the system more stable and operating costs lower. The

service life of DT membrane column can be as long as more than

three years.

| Model | DTRO3-8042-75 | DTRO3-8042-90 | DTRO3-8042-120 |

| Designed pressure bar | 75 | 90 | 120 |

| Sexual water production gpd (m³/d) | 2220(10.1) | 2220(10.1) | 2220(10.1) |

| Desalination rate% | 97.50% | 97.50% | 97.50% |

| Test solution | 2,000mg/LNaCl solution,pH7.5 | ||

| Recommended single recycling | 8% | ||

| Test pressure | 1.50MPa(225psi) | ||

| Strip test temperature | 25±1℃ | ||

| Single piece recovery rate | 8% | ||

| Influent flow (m³/h) | 0.50-1.20 | ||

| Maximum withstand temperature | 40℃ | ||

| Operating residual chlorine tolerance value | <0.1mg/L | ||

| For maximum water inlet | 20 | ||

| The maximum pressure loss of a single membrane | 100psi(0.7Mpa) | ||

| Software runs PH | 2.0-11.0 | ||

| Chemical Cleaning | 1.0-12.0 | ||

| Shipping status | Wet | ||

| Shipping weight (kg) | 75 | 95 | |

1) When the pH value is greater than 10, the maximum temperature

for continuous operation is 35 °C. When the influent water contains

free chlorine or other oxidizing substances, the

Because its oxidizing properties can seriously damage the

performance of the membrane, users are advised to remove free

chlorine or other oxidizing substances in the pretreatment.

Before each start-up, the pressure of less than 0.2MPa must be

used, and the flow rate of each DT membrane should not be higher

than 600L/H to discharge the membrane module.

The high-pressure pump can be started only after the air is

completely filled with water for 5 minutes;

2) The recommended water intake of each DT membrane module is

800-1200L/H, and the flow rate cannot exceed this flow range at any

time during normal operation.

It is recommended that each membrane enters 1000L/H of water;

3) In order to prevent the tightening thick nut (part number 2)

from loosening due to vibration during transportation, a torque

wrench should be used when the new equipment is turned on.

Tighten the nut by hand with a torque of 110NM.

4) It is strictly forbidden to test the membrane module under the

condition of tap water. The size of the permeate center pipe of the

DT module is designed according to the high-concentration salt

water condition, and the low salt water

Under high pressure, the fresh water flow is too large and cannot

flow out in time, which will cause the back pressure of the

diaphragm to damage the module. For test conditions, please consult

Zhejiang Tefen Environmental Technology

limited.