Add to Cart

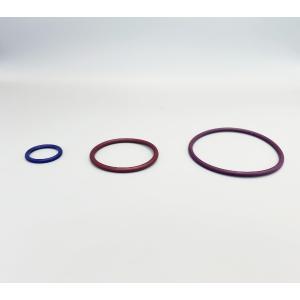

PTFE surface coating has excellent adhesion and friction performance compared with traditional coating

What are PTFE coatings?

PTFE coatings (Polytetrafluoroethylene) are non-stick, fluoropolymer, high temp coatings. They have a one-coat system or a two-coat system of a primer and topcoat and have several features that make them go-to coatings. This specific type of coating has the highest operating temperature of all fluoropolymers at 500°F, a low coefficient of friction, as well as good chemical resistance and abrasion resistance. Its non-reactive properties, due to strong carbon–fluorine bonds, makes this coating great for applications that must hold up against volatile and corrosive chemicals

| MATERIAL | PTFE COATING |

| COLOR | COLOR |

| advantage | Easier installation - increased lubricity reduces assembly time Easier identification of parts by color coding - by size or material Extend wear life - reduce corrosion, degradation, and downtime Resistance to dirt and debris contamination - no messy oil-based lubricants Reduce the risk of repeated injury (carpal tunnel syndrome) The surface coating can make a difference between a smooth running machine and frequent maintenance. Damage to the O-ring will cause the machine to shut down, which means loss of productivity and reduced profits. Extend the service life of important parts by adding surface coating |

| Application field | Bakeware, Automotive, Chemical, and Oil & Gas chemical industry, electrical and electronic industry, mechanical industry, aviation and other fields. |

| Operating temperature | -30 °C to 260 ° C |

| function | Easier identification of parts by color coding - by size or material |