Add to Cart

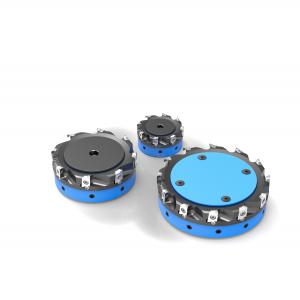

FMP-BE shell face milling cutter for face and shoulder milling BEHW1204 insert type PCD PCBN milling tools

| Specification | Inventory | D | D1 | D2 | D3 | L | Ap max | Z | kg | max RPM | Material |

| FMP040SA16-BE12-06 | 040401060013 | 40 | 16 | 36 | —— | 40 | 11 | 6 | 0.36 | 40000 | Steel |

| FMP050SA22-BE12-08 | 040401060005 | 50 | 22 | 45 | —— | 40 | 11 | 8 | 0.55 | 35100 | Steel |

| FMP063SA22-BE12-10 | 040401060006 | 63 | 22 | 45 | —— | 40 | 11 | 10 | 0.75 | 30200 | Steel |

| FMP080SA27-BE12-12 | ( 040401060007 | 80 | 27 | 50 | —— | 50 | 11 | 12 | 0.96 | 27500 | Steel+Auminium |

| FMP100SB32-BE12-16 | 040401060008 | 100 | 32 | 70 | —— | 50 | 11 | 16 | 1.45 | 23800 | Steel+Auminium |

| FMP125SB40-BE12-20 | 040401060009 | 125 | 40 | 90 | —— | 63 | 11 | 20 | 2.40 | 19100 | Steel+Auminium |

| FMP160SC40-BE12-24 | 040401060010 | 160 | 40 | 115 | 66.7 | 63 | 11 | 24 | 3.00 | 1 4900 | Steel+Auminium |

| FMP200SC60-BE12-30 | 040401060011 | 200 | 60 | 150 | 101.6 | 63 | 11 | 30 | 4.25 | 11 900 | Steel+Auminium |

| FMP250SC60-BE12-36 | 040401060012 | 250 | 60 | 200 | 101.6 | 63 | 11 | 36 | 6.50 | 9550 | Steel+Auminium |

| Cutters delivered assembled with spare parts, but without inserts, dynamically balanced to G2.5 at 25000 RPM unit: mm | |||||||||||

Worldia FMP-BE Milling Cutters were developed for high-speed machining of light metal on even small-size machining centers with precision spindles. Thanks to the innovative Bimetal Aluminium/ Steel body design, requirements for low weight, low inertia, and precise balancing to allow high spindle acceleration, high strength, and wear resistance are met at the same time. Cutters from diameters 80 to 160 mm can be mounted to the same adaptor, whereas e.g. the weight of a diameter 160 mm cutter with BT30 adaptor does not exceed 3 kg.

|

1. Aluminium Alloy/ Steel Bimetal design- - Al center body for weight reduction - Hardened Steel ring for high rigidity and wear resistance, therefore longer cutter life versus cutters with Aluminium body 2. High precision insert pocket seats keeping0,02 mm axial runout without insert adjustment 3. As a standard, each pocket can also be adjusted to um axial runout within a 0,1 mm range 4. BEHW inserts are available in a variety of materials, lead angles, wiper, and corner designs for many different applications in face and shoulder milling roughing and finishing 5. Separation between insert positioning face and cutting edge to protect cutting edge and to simplify the use of overlapped or retipped inserts 6. Inserts with 2 cutting edges and relap/ retip service to reduce tooling cost per part 7. Internal coolant through the cutter body |

Worldia's portfolio comprises a variety of different PCD and CVD materials that will be selected based on your specific application requirements. Below grades are a selection that covers the most common applications. |

| Workpiece Material | Grade | Grain size (um) | Characteristics | Application |

| N | PD10E | 10 | PD10E is the universal grade in the market. It's the first choice for many applications where a 9o0d balance of toughness and wear resistance is required. | This grade is commonly used for non-ferrous finishing applications. Other successful applications include machining of wood, MDF, low-medium content silicon aluminum aly, carbide, hard rubber, graphite and so on. |

| PD32E | 2~30 | PD32E has a unique combination of wear resistance, edge strength, and edge quality It contains a carefully selected mix of micron diamond (between 2 - 30 um). The combination of these particle sizes and a specially developed high pressure sintering process produces a structure with extreme abrasion resistance and good thermal stability. | Application areas include the machining of abrasive workpieces such as MMC, high silicon aluminum alloys as well as the machining of carbide, hard rubber, graphite and other materials. |

Workpiece: Motor end cover Spindle: Single spindle Maximum speed:16000RPM Adaptor: BT40 | |

Workpiece: Gearbox housing for commercial vehicles Spindle: Single spindle Maximum speed: 16000RPM Adaptor: BT50 | |

Workpiece: Cylinder head Material: ALSi10MgCu Spindle: Single spindle Maximum speed: 12000RPM Adaptor: HSK63 Processing type: Surface milling Processing time: 1 Surface finish: Ra3.2 | |

Workpiece: Guideways Spindle: Single spindle Maximum speed: 8000RPM Surface finish: Ra0.4 Hardness: HB180 |

| Technology Consulting and Custom Tool Design | After careful study of your requirements, our engineers suggest the

most efficient cutting process and tools. If required, design tools exactly to your needs. |

| Tool Assembly and Setting | If requested, we assemble the cutters with inserts and adjust them before delivery |

| Insert Retipping and Relapping | We offer retipping to same insert size underlapping at attractive conditions |