Add to Cart

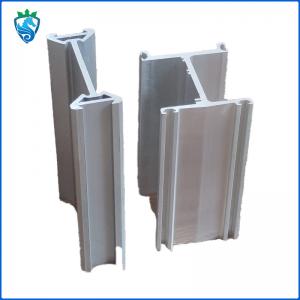

Sliding Slim Casement Hardware Beautiful Picture Aluminum And Door

Aluminium Window Profiles

Basic Information

|

|

| Aluminum alloy extruded profiles |

|

|

|

|

|

|

| As customer's requestments |

|

|

Product Display

Processing technology

1. The processing and production of aluminum doors and windows for

broken bridges should be carried out in the factory, not on the

construction site. The production of doors and windows should meet

the requirements of design and installation and acceptance

specifications for aluminum alloy doors and windows. The frames of

aluminum alloy doors and windows should be installed firmly.

Flexible opening, there should be a drain hole at the window sill,

and a limit device should be set. Fasteners should comply with the

relevant technical regulations; hardware models, specifications and

performance should comply with the current national standards.

2. The processing of the drainage holes on the slideway of the

sliding window should follow the principle of the outer hole of the

inner fan and the inner hole of the outer fan to ensure the sealing

performance of the door and window, especially the sliding window

with the horizontal top horizontal direction.

3. Before assembling the broken bridge aluminum doors and windows,

the end processing burrs should be removed, and the end nodes and

profile joints must be sealed with waterproof glue and other

sealing measures to prevent structural water seepage.

4. The structural assembly assembly of the hidden frame window must

be made and maintained in a purified room.

The dust, oil stains and other contaminants on the bonding surface

of the glass and aluminum frame must be removed with a solvent; a

clean dry cloth should be replaced every time a component or piece

of glass is cleaned; the solvent should be poured on the cloth, and

it is strictly forbidden for the cloth to touch the solvent bottle

mouth. The glue injection must be full, there should be no bubbles

or leakage, and the surface of the glue joint should be smooth and

smooth; the remaining glue in the glue joint should not be reused.

Certificates and Honors

Factory display

Company Profile

Jiangyin Longkang Metal Products Co., Ltd. is located in Zhouzhuang

Town, Jiangyin City - the largest aluminum extrusion profile

production base. Covering an area of more than 35,000 square meters

with more than 350 employees. We focus on metal customization,

special-shaped aluminum profiles, aluminum profiles, aluminum

tubes, rail transit series, doors and windows aluminum profiles,

heat sinks, CNC processed aluminum profiles, interior decoration

series, bending series, etc. We also have precision anodizing and

various surface treatments, such as PVC film, wood grain,

electrophoresis, powder coating, anodizing, etc. After more than 20

years of development, The company has become a modern aluminum

production enterprise with perfect quality management system.

The company has the ability to develop and design molds

independently, we can produce any extruded aluminum profiles

according to your mechanical drawing or sample. Longkang has 10

extrusion production lines (600-3500 tons), one automatic oxidation

electrophoresis production line, vertical and horizontal spraying

production line per each, and a variety of advanced supporting

production, processing and testing equipments. There are also CNT

digital control drilling and milling machine(CNC), double head saw,

hydraulic saw and punching machine in our processing workshop. The

complete technological process can benefit to reduce the production

turnover times for semi-finished products, to avoid the damage

during transportation, improve the production efficiency, reduce

the cost of production,and to ensure the quality and delivery time.

Efficiently treating our customers as partners with sincerity,

specialization and satisfaction is our managerial principle.

Attributed to the backup of a dedicated technical team, filled with

wide and profound knowledge and practice in aluminum profile and

world trade for 20 years, the company owns rich experience in

product quality control and profile physical properties such as

Hardness, Stretchability, Flatness, Straightness, and Tolerance

etc. In line with the principle of sharing the preferential cost

and joint development, the company has formed an interest community

for years with its customers at home and abroad. Sincerely to build

up a pleasant mutual trust, cooperative, win-win and value-added

sustainable partnership is what we are achieving to grow together

with you!

FAQ

Q: Can you send me the product catalog and price?

A: Leave your e-mail or other contact information, the product

catalog will be provided here

The real-time price needs to confirm the specific product

specifications and quantity, so the price can be calculated for you

only when you provide drawings or plans, etc.

Q: Do you provide samples?

A: Yes (special customized samples need to provide drawings).

Q: What is the thickness of the anodizing? Can you do 12um?

A: Our normal thickness is about 10 um. Yes, we can do 15 microns

and above.