Add to Cart

Brazed Plate Heat Exchanger for Hydrualic Oil Cooler /Air Compressor Oil Cooler

BAODE Plate Heat Exchanger Co., Ltd. Is a Chinese Plate Heat

Exchanger manufacturer specialized in development,Production and

global marketing of pasteurizer heat exchangers. Since the very

start in 2004 BAODE has grown to one of the leading companies in

China Plate heat exchanger market and has developed a big range of

pasteurizer heat exchangers for any task.

Our main products are Brazed pasteurizer heat exchanger &

Gasket pasteurizer heat exchanger & Air cross pasteurizer heat

exchanger (Flat pasteurizer heat exchanger and frame and

pasteurizer heat exchanger, welded pasteurizer heat exchanger).

Braze pasteurizer heat exchanger include Copper brazed pasteurizer

heat exchanger and Nickel brazed pasteurizer heat exchanger.

Our mission is to help you to achieve the optimum solution with

regards to performance efficiency, payback and energy conservation,

whatever the application. This is based on a marketing orientation

concept which makes us a highly valuable partner. Our combined

experience in the pasteurizer heat exchanger industry, allow us

giving the best technical recommendation for our customers and end

users for applications such as:Refrigeration Systems that

includes,HVAC includes,Other Industrial applications.

Description

Baode DOC oil cooler are used to exchange heat between oil &

collant. They are high performance components and provide a high

level of efficiency combined with compact dimensions and low

weight. Their efficiency reduces the amount of cooling water

required for heat transfer which results in low operating costs.

Features

Plates and connections are manufactured from stainless steel to

AISI 316, 1.4401, vacuum–brazed with copper / stainless. The

special molding of the plates produces the turbulent flow necessary

for effective heat transfer and provides the plate heat exchanger

with a high level of mechanical strength. Nickel & Stainless

brazed option available.

Operating Details

Medium:

•Water glycol (coolants)

•HFC operating fluids

•Water

•Oil

Contamination:

The quantity of particles in suspension should be less than 10

mg/l.

Particle size < 0.6 mm (spherical).

Thread–like particles cause a rapid rise in pressure drops.

Temperature Range:

•50° to 437°F (10° to 225°C)

(freezing point and boiling point must be taken into

consideration!)

Pressure:

•Max Design pressure. 30bar / 45bar

•Test pressure: 45bar/60bar

Corrosion:

The following limits refer to a pH value of 7

•free chlorine, CL2 < 0.5 ppm

•chloride ions CL

< 700 ppm at 20 °C

< 200 ppm at 50 °C

Other Limits:

•ph 7 – 10

•sulphate SO4 2– <100 ppm

•[H CO3 –] / [SO4 2– ] >1

•ammonia, NH3 <10 ppm

•free CO < 10 ppm

The following ions are not corrosive under normal condi- tions:

phosphate, nitrate, nitrite, iron, manganese, sodium and potassium

Applictions:

•Agricultural

•Automotive

•Construction

•Gearboxes

•Industrial

•Elevators

•Commercial Municipal

•Power Generation

•Pulp & Paper

•Railways

•Shipbuilding

•Steel / Heavy Industry

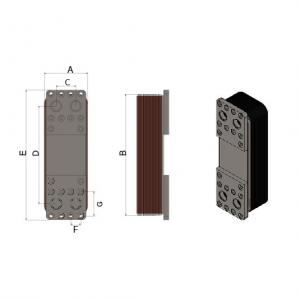

| Model | A | B | C | D | E | F | G |

| DOC30 | 111 | 310 | 50 | 250 | 332 | 28 | 62 |

| DOC60 | 111 | 525 | 50 | 466 | 548 | 28 | 62 |

| DOC110 | 191 | 616 | 92 | 519 | 635 | 40 | 90 |

ModelBL1

Short delivery time.

High quality

Reasonable price

Customer made

Know-how design and customer support

Certified by ISO9001, CE, UL, WRAS, RoHS, CCS etc.

| Material | |

| Cover plates material | Stainless Steel |

| Flow plates | Stainless Steel |

| Connections | Stainless Steel |

| Brazing material | Copper / Ni / Stainless |