Add to Cart

Product Description

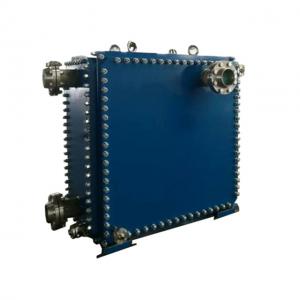

Fully welded plate heat exchangers are divided into non-detachable fully welded plate heat exchangers, 2-sided detachable fully welded plate heat exchangers, 4-sided detachable fully welded plate heat exchangers (Compbloc) and wide channel fully welded plate heat exchangers .

Read below to learn more about some of the common ways that customers all over the globe use Compabloc heat exchangers to improve the sustainability of their operations.

Condensing duties

Compabloc’s short flow path and large cross-flow area ensure low

pressure drop and high efficiency, making it ideal for condensing

duties. High heat transfer rates and low fouling, make Compabloc

the best choice for long-term efficiency and consistent

performance. As a result, Compabloc performs condensing duties 2-4

times more efficiently than traditional solutions.

Vapour enters from the top of the unit and condenses on the cold

plates as it passes through the plate pack, with condensate exiting

at the bottom.

If the vapour contains non-condensable gases, can design a two-pass

arrangement on the condensing side that permits gas/liquid

separation inside Compabloc, eliminating any need for a separator

unit. Condensation takes place primarily in the first pass.

Sub-cooling of non-condensable gases is achieved in the second

pass, which also serves as a mist eliminator.

Advantages:

Fully Welded without Gasket

High Temperature /Pressure Resistance

High Heat Exchange Efficiency

Compact Structure:

Light Weight with Small Footprint

Recommended Applications:

Petrochemical

Oil & Gas

Energy Power

Metallurgy

Biomedical

Baode company specializes in supplying various types of gasket plate heat exchanger, brazed plate heat exchanger, frame and plate heat exchanger gasket, providing cleaning services and refurbishing solutions. The products are widely used in power, metallurgy, chemical industry, food and beverage, sugar making, paper making, textile, Marine, heating and air conditioning, refrigeration and other fields. We are willing to work with you to discuss your various problems in the application of heat exchange system, to give you quality service.

| Model | Standard Pressure (bar) | Standard Temp. Range (°C) | Max.Dimension (mm) A*A*B |

| CP15 | FV-32 | -40 - 300 | 280*280*540 |

| CP20 | FV-32 | -40 - 300 | 430*430*730 |

| CP30 | FV-32 | -40 - 300 | 500*500*1070 |

| CP40 | FV-32 | -40 - 300 | 600*600*1400 |

| CP50 | FV-32 | -40 - 300 | 840*840*2050 |

| CP75 | FV-32 | -40 - 300 | 1240*1240*3600 |

| CP120 | FV-32 | -40 - 300 | 2190*2190*3500 |