Add to Cart

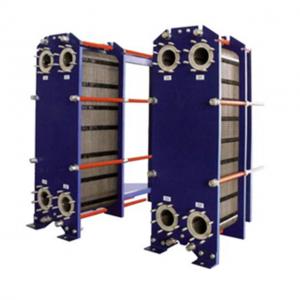

Air Conditioner Radiator Air Cooler Refrigerator Gasket Plate Type

Heater Heat Exchanger

The gasket plate heat exchanger is the ideal equipment for

liquid-liquid and liquid-steam heat exchange. It is a new type of

high efficiency heat exchanger made of a series of metal sheets

with a certain corrugated shape. The unique structure makes it form

a good advantage in many types of heat exchangers.

Structural principle

The removable plate heat exchanger is made of many stamped

corrugated sheets at a certain interval, sealed around by gaskets,

and superimposed by the frame and compression spiral. The four

corner holes of the plate and gasket form a fluid distribution tube

and a collection tube, and at the same time reasonably separate the

hot and cold fluids, so that they flow in the flow channel on both

sides of each plate, and carry out heat exchange through the plate.

Working principle

Plate cooler is a heat exchanger made of a thin metal plate pressed

into a heat exchange plate with a certain corrugated shape, and

then stacked, and fastened by cleats and bolts. A thin rectangular

channel is formed between the various plates, and heat is exchanged

through the half plates. The working fluid flows through a narrow,

winding channel formed between the two plates. The hot and cold

fluids pass through the flow path successively, and there is a

partition plate in the middle to separate the fluids, and the heat

is transferred through the plate.

Its structure and heat transfer principle determine that it has the

characteristics of compact structure, small footprint, high heat

transfer efficiency, large operational flexibility, wide

application range, small heat loss, convenient installation and

cleaning.

| Model | BH100B / BH100H | |

| Cross Reference | M10M, M10B | |

| Height, H [mm] | 1084 | 1084 |

| Width, W [mm] | 470 | 470 |

| Min standard length, L [mm] | 700 | 700 |

| Max standard length, L [mm] | 2300 | 2300 |

| Vertical port distance, VC [mm] | 719 | 719 |

| Horizontal port distance, HC [mm] | 225 | 225 |

| Max temperature [°C] | 180 | 180 |

| Max pressure [barg] | 10 | 16 |

| Flange size | DN100/4'' | DN0100/4'' |

| Max. flow rate [kg/s] | 50 | |

(Measurment in mm, N means the number of the plates)

| Material of Plate | Suited Liquid Kinds | ||

| Stainless Steel (AISI304.316 Etc) | Pure Water, Normal Water, Oil for eating, Mineral Oil | ||

| Ti, Ti-pd | Sea Water, Saline Water, Mineral Water | ||

| 20Cr, 18Ni, 6Mo (254SMO) | Dilute Sulphuric Acid, Organic Water Solution | ||

| Ni | High-temp and concentration caustic soda | ||

| Hastelloy (C276, D205, B2G) | Concentration Sulphuric Acid, Hydrochloric acid, Phosphoric acid | ||

| Material of Gasket | Operating Temperature ° C | Suited Liquid Kinds | |

| NBR | -15~+135° C | Water, Sea Water, Mineral Oil, Salinous Water | |

| EPDM | -25~+180° C | Hot Water, Steam, Acid, Alkali | |

| F26 | -55~+230° C | Acid, Alkali | |

| TPF | -0~+160° C | High Concentrated Acid, Alkali, High temperature Oil, Steam | |

The gasket plate heat exchanger, with its unique design and

efficient performance, has been widely used in various industrial

and civil fields. It is highly efficient, compact, lightweight and

easy to maintain, making it a leader in modern heat transfer

technology.

The biggest feature of the gasket plate heat exchanger is its high

efficiency. Due to its unique plate design, the hot and cold fluids

flow in a very small flow channel, which greatly improves the heat

transfer efficiency. At the same time, due to the turbulent state

of the fluid, the heat transfer process is more efficient.