Add to Cart

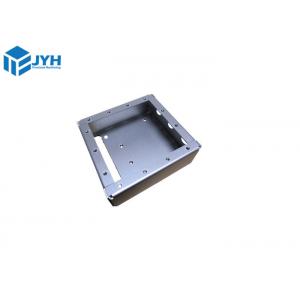

Advanced Sheet Metal Fabrication Galvanized Sheet And Prototype Metal Parts

JYH Precision Sheet Metal Fabrication Service

Our experienced staff can help you develop your product idea and build a conceptual or functional prototype. We can help you achieve your production targets for high-quality sheet metal components. We can also save you time, money and factory space by providing kitting and assembly services.

JYH Precision Quality assurance

Our unwavering commitment to product quality assurance in sheet metal fabrication is evident in every aspect of our process.

Our ISO 9001:2015, ISO 13485, and AS9100D certifications reinforce our commitment to maintaining the highest standards.

Why use JYH’s for sheet metal fabrication

Fast quoting & DFM feedback

Build and edit your quote within 30 minutes. Review your parts for manufacturability and assess the cost of different materials,

processes and lead times for your project in real time.

Quality & reliability

Dedicated JYH’s team to ensure your parts consistently meet your quality expectations. We also offer phone, email and chat support for any concerns or questions you may have.

JYH Precision Available materials for sheet metal:

Below is a list of our standard available metals for sheet metal fabrication

Aluminum | Stainless steel | Mild steel | Copper |

| 5052/6061 | 304/316 | 1018 | C110 |

Other material can choose:

Carbon-Fiber Composites

Hybrid laser cutting machines, or machines that combine CO2 and

fiber lasers together into a single laser, are best for cutting

carbon-fiber composites. Carbon fiber is typically woven together

into materials and then coated with a polymer matrix to secure the

material together. The CO2 laser vaporizes the polymer matrix while

the fiber laser cuts through the carbon fibers.

Stainless Steel

Stainless steel is a material commonly used for laser-cut

prototypes. Stainless steel, along with most metals, can be

difficult to cut using CO2 lasers because of its high reflectivity.

Laser cutting stainless steel is most easily accomplished using a

fiber laser. However, coating the workpiece with a metal marking

paste to reduce its reflectivity makes it capable of being cut by a

CO2 laser.

Aluminum

Aluminum is another material that is commonly used in laser-cut

prototypes. As with stainless steel, aluminum’s reflectivity makes

it difficult to cut using CO2 lasers unless its reflectivity is

reduced with an appropriate surface treatment. Fiber lasers are the

best option when laser cutting aluminum workpieces.

PETG

PETG (polyethylene terephthalate glycol) is a type of thermoplastic

polyester that is commonly used in food and beverage containers,

packaging, medical devices, and machine guards. Its low

vaporization temperature makes it exceptionally easy to cut with

any type of laser cutting system.

Why use JYH’s for sheet metal fabrication?

Fast quoting & Free DFM feedback | High Quality & reliability |

Build and edit your quote within 30 minutes. Review your parts for manufacturability and assess the cost of different materials, processes and lead times for your project in real time. | Dedicated JYH’s team to ensure your parts consistently meet your quality expectations. We also offer phone, email and chat support for any concerns or questions you may have. |

JYH Precision Sheet Metal Fabrication Standards

| Dimension Detail | Metric Units | Imperial Units |

Edge to edge, single surface | +/- 0.127 mm | +/- 0.005 in. |

Edge to hole, single surface | +/- 0.127 mm | +/- 0.005 in. |

Hole to hole, single surface | +/- 0.127 mm | +/- 0.005 in. |

Bend to edge / hole, single surface | +/- 0.254 mm | +/- 0.010 in. |

Edge to feature, multiple surface | +/- 0.762 mm | +/- 0.030 in. |

Over formed part, multiple surface | +/- 0.762 mm | +/- 0.030 in. |

JYH Precision surface finishes for sheet metal

Surface finishes are applied after machining and can change the appearance, surface roughness, hardness and chemical resistance of the produced parts.

Picture of surface finish | Name | Description |

Standard surface finish | This is our standard finish. Parts as delivered as cut and bent, no additional treatment applied. Sharp edges are broken and deburred for safe handling. | |

| Brushed | Parts are manually brushed with grit #180 after cutting and bending. Sharp edges are broken and deburred for safe handling. Ideal to reduce the surface roughness of a part. | |

| Brused + Anodized type II | Parts are dipped in an anodizing bath (type II) after manual brushing. Ideal for increasing the corrosion resistance of the part. Ideal for increasing the corrosion resistance of the part. | |

| Powder coating | Powder coating layer is applied directly after fabrication. Sharp edges are broken and deburred for safe handling. | |

| Black oxidization | Parts are dipped in a black oxide bath after fabrication. Ideal to improve improve corrosion resistance and minimize light reflection in steel components. |

Available sheet metal fabrication processes

Gives you easy access to sheet metal fabrication capabilities to serve all your manufacturing needs.

| Name | Description | Allowable sheet thickness |

| Laser cutting | This manufacturing process uses a high-power laser beam to cut a material sheet. | 1-5mm(depending on material) |

| Bending | This manufacturing process uses dies to produce a U-shape,V- shape or channel shape along a straight axis in ductile materials | 1-6mm (depending on material) |

JYH Precision Shipping way

JYH Precision Payment method

JYH Precision workshop

Frequently Asked Questions

1. What are the tolerances for fabricated parts?

Sheet metal fabrication tolerances refer to the acceptable deviations for features of sheet metal parts required for accurate and consistent installation and integration.For sheet metal parts, ISO 2768-mk is usually used to ensure proper control of the elements of geometry and size.

The following will show you 7 tolerance standards range of linear and angular dimensions, flatness & straightness, cylindricity, and circularity.

2. How much does sheet metal fabrication cost?

Every aspect of a sheet metal fabrication project comes with an associated cost — the design, possible prototype, finishing processes, and others. Asides from the process itself, materials also cost money.

3.Whatis the lead time for our project?

It need to based on your product size and QTY/Structure.

JYH is your best partner of Sheet Metal Enclosure Fabrication And Production Stainless Steel Sheet Parts!