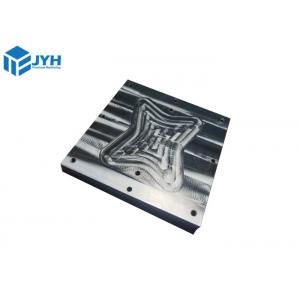

Product Details

CNC Machining Steel Series Service For Stainless Steel 304 With

Precise Tolerance

We can provide Precise Tolerance with +/- 0.001mm of CNC Machining

Steel Series Service. JYH's steel CNC machining service is a good

choice for high quality, ISO 9001 certified parts.

We have a complete set of production process system. For batch

production projects, we have certain control process,

strict implementation of the first sample confirmation process,

optimization of production procedures, to achieve high efficiency,

low cost, high quality.

Here is the Type and Tolerance for your reference

Type

| Tolerance |

Linear dimension

| +/- 0.025 mm

+/- 0.001 inch

|

| Hole diameters (not reamed) | +/- 0.025 mm

+/- 0.001 inch

|

| Shaft diameters | +/- 0.025 mm

+/- 0.001 inch

|

| Part size limit | 950 * 650 *550 mm

38.0 * 22.5 * 22.5 inch |

If a CAD model only is supplied the following tolerances apply to

machined surfaces:

●For features of size (Length, width, height, diameter) and

location (position,concentricity, symmetry) +/- 0.005” .

●For features of orientation (parallelism and perpendicularity) and

form (cylindrical, flflatness, circularity, and

straightness) apply tolerances as follows:

We have an ensuring Quality sysem for our clients.

Advantages and Benefits of Steel CNC Machining:

- Rapid Turnaround: Using the latest in steel CNC machining and

online quoting technologies, JYH produces highly accurate, quick

turn machined parts in as fast as 1- 2 days.

|

- Custom Finishes: Select from a variety of finishes on metal,built

to precise design specifications.

|

- Material Selection: Choose from over 50 metal, Metal milling offers

a variety of certified materials.

|

- Precision: Offers high-precision tolerances ranging from +/-0.001″

– 0.005″, depending on customer needs.

|

FAQ:

1-What is the advantage of working with JYH company? Why should I

choose your company to make my parts? - Our industrial CNC machining, and injection moulding services

provide parts made directly from the customer’s 3D CAD model,

reducing the likelihood of errors. Proprietary software automates

toolpath generation to decrease manufacturing times and reduce

costs.

|

2-What industries use JYH services? - We serve a variety of industries including medical device,

automotive, lighting,Robot, aerospace,consumer product.

|

3-How many machines do you have? - We currently have more than 60 machines: roughly 40+ CNC mills and

30 Injection mold machine,10+ 3D printers. With our long history of

growth, this number is always changing.

|

4-How do I get a quote? - To get a quote for all of our services, simply send us your 3D CAD

model to us. You'll get an interactive quote within hours with free

design feedback. If there are problem areas in the submitted

design,we will provide free design feedback(DFM).

|

5-What types of files do you accept? - We can accept native SolidWorks or ProE files as well as solid 3D

CAD models from other CAD systems output in IGES (.igs), STEP

(.stp), ACIS (.sat) or Parasolid (.x_t or .x_b) format.

|

6-Do you provide First Article of Inspection (FAI) Service? - We can provide FAI as part of the unlimited offer.

|

7-What is payment term does your company can be acceptable? - We can accept T/T (50 prepayment should be paid before start the

production; the 50% remaining payment should be paid after finish

the project).

|

8-What is your lead time after we place an order with you?

Once get your order,we will sart to order review and it is usually

takes 3-5 work days,but it should be finally to the actual product

quantity, structure, post-processing.

|

Our workshop

JYH CNC Precision Machining is your best partner!

Company Profile

JYH specialize in manufacturing high-end products, good at

manufacturing Aerospace area/Military/Robot/New energy . With more than 100 sets of equipment and thousands of measurement

and inspection equipment to ensure quality and delivery time. We produce simple and complex prototypes and end-use parts with

powerful and efficient manufacturing capabilities. All our products

meet strict tolerance criteria and quality standards, making us the

leading on-demand manufacturing company in China.We offer

high-quality products across several industries,includes

Automotive/Aerospace/Medical Devices/Robotics. Products are

exported to Spain, Malaysia, Thailand, Israel, France, Germany,

Britain, Italy, Sudan, the United States, Canada.