Add to Cart

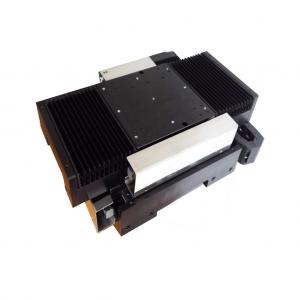

150*150mm Effective Stroke Linear Motor Stage High Positioning Accuracy

SUPT linear motor with high-precision grating, magnetic grid andhigh-precision guide rail. High speed, high acceleration operation.smooth movement, good stability, high precision. With suitableencoder and guide rail, the position accuracy can reach 0.1-5um.Positioning accuracy: 土2um, repeatability: 0.5um,straightness+3um Platform structure can be customized according to differenttechnicalrequirements ofcustomers.

Constitute a linear motor platform

Typical platform configuration:

Base general use castings&alu, Is the foundation of the entire

platform, To fix the motor, rail, grating, stoppers etc.

Motot including stator & mover,A stator fixed on the base,Mover

and load platform to be connected,Provide motive power.

Rail including linear rail and linear guide slider, load platform

is connected to the slider. Loading platform support load platform,

Scale of reading head is mounted on a motion platform.

Position feedback, including the scale and scanning head,

Grating mounted on the base,Scanning head and sports platfornto

connect Stopper on both sides of the base installation,

Ensure the safe operation of motor.

linear motor module:

The linear motor without iron core or with ironcoreis equipped with

high-precisiorgrating, magnetic grid and high-precision guide rail.

High speed, high accelerationoperation, smooth movement, good

stability, high precision. With suitable encodeand guide rail, the

position accuracy can reach 0.1-5um, Positioning

accuracy+2um.repeatability: 0.5umstraightness 3um Platform

structure can bedifferent technicalrequirements of customers,

SUPTcustomized according to (linear motor is adopted, and

high-precision grating, magnetic grid andhigh-precision guide rail

are configured. High speed, high acceleration operation.smooth

movement,good stability, high precision. With suitable encoder and

guiderail, the position accuracy can reach 0.1-5um Positioning

accuracy: 2um,repeatability accuracy: +0.5um, linearity: 3um

Platform structure can becustomized according to different

technical requirements of customers.

| Modules | T- | LC | 0080 | -100 | A | 01 | 30 | ||||

| LC: The plate has an iron core motor | Peak thrust | Stroke: mm | A: Raster | 01:0.1um | Motor linelength: | ||||||

| LU: U-type coreless motor | B: Maeicgid | 05:0.5 um | 30: 3m | ||||||||

| 10: lum | |||||||||||

The linear motor module platform has been widely used in multiple

fields, and its high accuracy, high-speed, and stability make it

suitable for many scenarios that require precise motion and

control. The following are the main application areas of the linear

motor module platform:

1. Semiconductor Manufacturing:The linear motor module platform is

used for precise wafer positioning, testing, and packaging

processes in semiconductor manufacturing. They can achieve

micrometer level position control, ensuring high precision and

consistency in semiconductor production.

2. Medical Equipment: In the medical field, linear motor module

platforms are commonly used in medical imaging equipment, surgical

robots, and precision detection equipment. They can achieve

high-precision motion, ensuring the safety and accuracy of medical

operations.

3. Optical Equipment: The linear motor module platform is used in

fields such as optical instruments, laser equipment, and

microscopes. They can achieve precise positioning and focusing of

optical components, improving the performance of optical systems.

4. Automated Production Line: In the manufacturing industry, linear

motor module platforms are used for material handling, assembly,

and testing on automated production lines. They can achieve

efficient and accurate material handling and assembly operations.

5. Aerospace: In the aerospace field, linear motor module platforms

can be used for flight simulators, satellite positioning, and

aviation equipment testing. They can simulate precise motion in

flight or space environments.

6. Precision machining: The linear motor module platform is widely

used in precision machining fields such as engraving, cutting,

stamping, etc. They can achieve precise machining of complex

shapes.

1.Travel: effective travel, used to calculate the the total travel of value force.

2.The direction of movement: horizontal or vertical installation 90 degree.

3.Load force: constant in the reverse direction of force on the motor, such as springs, etc.

4.Load weight: the total quality part of movement, including the quality slider

5.Movement Type: 1.point to point movement; 2.the reciprocation of the rule (e.g. scanning).

6.Velocity curve: 1.a trapezoidal speed curve; 2.triangular speed curve; 3.sine speed curve.