Add to Cart

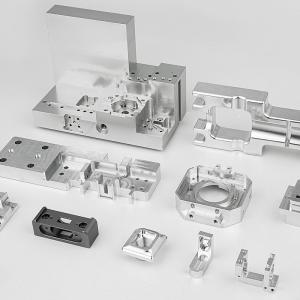

CNC Lathe Machining Service Large Part Aluminum Milling CNC Part

Milling Machines 6061 CNC Machining Aluminum Parts

What Are the Benefits of CNC Machining?

CNC machining offers several advantages, including:

1. Precision: CNC machines are capable of producing parts with exceptional precision, ensuring

consistent quality and eliminating human error.

2. Continuous Operation: CNC machines can operate 24/7 as long as they have a steady supply

of raw materials and fresh cutting tools.

Robotic systems can be employed for material loading and part unloading without the need for

human intervention.

Product Details

What raw materials can I use with CNC machining?

Virtually any sturdy and solid material can be subjected to CNC machining, including mild and

stainless steels, aluminum, brass, copper, magnesium, titanium, and a wide array of engineering plastics.

| Common Materials | |

| Name | Description |

Aluminum | High machinability and ductility, good strength-to-weight ratio. |

Stainless steel | High tensile strength, corrosion and temperature resistant. |

Mild steel | High machinability and weldability, high stiffness. |

Brass | Low friction, excellent electrical conductivity, golden appearance. |

Copper | Excellent thermal and electrical conductivity. |

Titanium | Excellent strength to weight ratio, used in aerospace, automotive and medical industries. |

ABS | Common thermoplastic, impact resistant, easy to machine. |

| Nylon | Excellent mechanical properties, thermal, chemical and abrasion resistant. |

| PEEK | High-performance thermoplastic, very high strength, thermal and chemical resistant. |

| Surface Finishes | ||

| Name | Applicable to | Machining marks |

| As machined | Metals, Plastics | Visible, light surface scratches |

| Smooth machining | ||

| Fine machining | Metals | Slightly visible |

| Polishing | Metals | Removed on primary surfaces |

| Bead blasting | Metals | Removed for non-cosmetic, removed on primary surfaces for cosmetic |

| Brushing | Metals | |

| Anodizing Type II | Aluminum | |

| Anodizing Type III | Aluminum | Visible under anodizing |

| Black oxide | Copper, Stainless steel, Alloy steel, Tool steel, Mild steel | Visible |

| Powder coating | Metals | Removed |

| Brushed + electropolishing | Stainless steel | Removed on Primary surfaces |

Specialist Industries

We’ve manufactured millions of parts for all sorts of applications,

but we’re especially knowledgeable in these areas.

1. Aerospace & aviation

2. Automotive

3. Industrial machinery

4. Consumer electronics

5. Robotics & automation

6. Medical

Company Profile

FAQ's

1. Can make design drawings for me?

We do not offer standalone product design services, but we do provide Design for Manufacturing

(DFM) reviews for all approved orders.

This means that we collaborate with our clients to optimize their 2D and 3D drawings, enhancing

manufacturability, resolving design issues, and reducing production expenses.

Learn more about preparing your CAD drawings for manufacturing.

2. How long does a quotation take?

Typically, we aim to provide a response within one days upon receiving an RFQ. If there is a delay

in generating the quote, we will promptly inform you.

3. How does our pricing compare to other suppliers?

When it comes to pricing, we offer a competitive advantage.

Typically, our prices for plastic injection

mold tools and CNC machined/turned parts are 25-45% lower than those of suppliers in North America

and Europe.

In contrast to Chinese suppliers, we do not compete solely on price. Instead, we prioritize delivering the

utmost quality, rapid responsiveness, and professional results to our clients.

4. How soon can I receive my parts?

We can produce quality parts in as little as two weeks if you

provide us with complete 2D and 3D CAD models.

However, more complex parts with special features may have longer lead times.

Request a quote to receive more precise lead times based on your specific project.

Regarding shipping, our primary method is air freight, which typically takes a few days for delivery from

China to Europe or North America.