Add to Cart

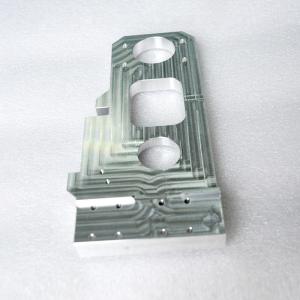

Aluminum CNC Milling Part CNC Machining Service Part OEM CNC Machining Part

CNC Milling is an automated machining process utilized for crafting both 2D and 3D CNC parts

through the subtraction of material from raw stock.

Manufacturing facilities employ CNC milling machines to enhance productivity and reduce

production time.

To create a CNC milled component, a block or sheet material is positioned on a table beneath

a spindle equipped with a cutting tool.

A computer controls various parameters, including tool selection, spindle rotation speed,

vertical spindle movement, and horizontal table motion.

This control enables tools like drills, taps, and end mills to remove material sections, shaping

them into desired forms.

Product Details

CNC milling encompasses a wide range of materials, primarily categorized into three major

groups: plastics, soft metals, and hard metals. These materials include aluminum, bronze,

copper, ceramics, plywood, steel, stone, wood, zinc, and numerous others.

The choice of material depends on ease of workability and desired properties, with those

offering favorable characteristics often being preferred in CNC milling applications.

| Common Materials for CNC Machining | |

| Material | Properties |

| Aluminum | 2024: Good fatigue resistance and strength; excellent toughness at moderate to high strength levels; improved fracture toughness |

| 6061: Excellent machinability, low cost, and versatility | |

| 7075: High strength, hardness, low weight, and heat tolerance | |

| Stainless Steel | Excellent machinability and outstanding uniformity; good workability and weldability, high ductility and formability |

| Steel Alloy | Mix of chromium, molybdenum, and manganese yields toughness, good torsional and fatigue strength |

| Brass | Versatile and highly attractive copper/zinc alloy with warm yellow color accommodates severe forming/drawing |

| Titanium | Excellent strength to weight ratio, used in aerospace, automotive, and medical industries |

| Copper | High ductility and high electrical and thermal conductivity; develops attractive blue-green surface patina over time |

| ABS | Excellent impact resistance, good mechanical properties, susceptible to solvents |

| Nylon | Excellent mechanical properties, high toughness, poor moisture resistance |

| POM | High stiffness, excellent thermal & electrical properties, relatively brittle |

CNC Machining Tolerances

Our standard tolerances are 0.05 microns, which meet the requirements for most commercial

and industrial applications.

Feel free to reach out to us if you require even tighter tolerances for specific projects.

| CNC Milling Tolerances | ||

| Limits for nominal size | Plastics | Metals |

| 0.5mm* to 3mm | ±0.1mm | ±0.05mm |

| Over 3mm to 6mm | ±0.1mm | ±0.05mm |

| Over 6mm to 30mm | ±0.2mm | ±0.10mm |

| Over 30mm to 120mm | ±0.3mm | ±0.15mm |

| Over 120mm to 400mm | ±0.5mm | ±0.20mm |

| Over 400mm to 1000mm | ±0.8mm | ±0.30mm |

| Over 1000mm to 2000mm | ±1.2mm | ±0.50mm |

| Over 2000mm to 4000mm | ±2.0mm | |

*Please clearly indicate tolerances for nominal sizes, below 0.5mm on your technical drawing. | ||

Common Applications

The following industries gain the most from CNC machining:

1. Medical 2. Electronics 3. Publishing

4. Transportation 5. Woodwork 6. Construction

7. Agriculture 8. Aerospace 9. Manufacturing

10. Automotive 11. Firearms 12. Metalwork

Company Profile

FAQ's

1. Is CNC milling expensive?

CNC milling costs can vary, but there are strategies to help minimize expenses.

Designing simpler parts and using standard-sized tooling can enhance the likelihood of

cost-effective production.

Additionally, incorporating internal corner radii, avoiding thin walls or sections, and opting for

larger features over smaller ones can all contribute to cost savings in CNC machining.

2. How quickly can I get my parts?

We can produce high-quality parts in as little as two weeks if you furnish us with comprehensive

2D and 3D CAD models.

However, for more intricate parts with additional requirements or special features, the lead time

may be longer. Feel free to request a quote to obtain precise lead times tailored to your project.

In terms of shipping, the majority of our shipments are dispatched via air freight.

The transit time from China to Europe or North America typically takes a few days.

3. How does you ensure the quality of my parts?

Our commitment to ensuring the quality of your parts includes a comprehensive approach:

1. Design for Manufacturing (DFM) Review: After your order is confirmed, we conduct a thorough

DFM review to identify and address any potential issues that could impact part quality.

2. Incoming Material Inspection: All incoming materials undergo rigorous inspection and

verification using advanced testing equipment to ensure they meet our quality standards.

3. Final Inspection Reports: Before shipment, each part undergoes a final inspection.

We provide detailed inspection reports, giving you complete visibility into the quality of your parts.

4. Real-time Inspection Data: We have the capability to share inspection data with you in real-time.

This collaborative approach allows us to address any quality concerns during the production process,

ensuring that your specifications and expectations are met.

Our commitment to quality control is integral to delivering parts that meet your exacting standards.