Add to Cart

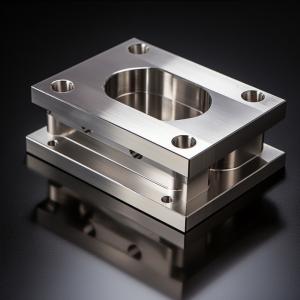

We possess extensive CNC machining capabilities, crafting a diverse range of parts, from

straightforward "as machined" workholdings to intricate geometries. Our manufacturing facilities

are equipped with a variety of CNC mills and turning centers, and upon request, we can utilize EDM

and grinders.

Embracing precision, we provide tolerances as tight as 0.05 mm (0.0020 in), coupled with swift

lead times starting from just one business day.

Product Details

Our CNC machining capabilities encompass a diverse range of materials, including carbon alloys,

aluminum, brass, stainless steel, high nickel alloys, and engineered plastics.

We pride ourselves on assisting you in selecting the optimal material for your specific application.

Whether you are considering materials from our standard list or exploring options beyond,

our expertise ensures the best choices for your needs.

| Common Materials | |

| Name | Description |

| Aluminum | High machinability and ductility, good strength-to-weight ratio. |

| Stainless steel | High tensile strength, corrosion and temperature resistant. |

| Mild steel | High machinability and weldability, high stiffness. |

| Brass | Low friction, excellent electrical conductivity, golden appearance. |

| Copper | Excellent thermal and electrical conductivity. |

| Titanium | Excellent strength to weight ratio, used in aerospace, automotive and medical industries. |

| ABS | Common thermoplastic, impact resistant, easy to machine. |

| Nylon | Excellent mechanical properties, thermal, chemical and abrasion resistant. |

| POM | High stiffness, high accuracy, low friction, easy to machine. |

Post-processing and surface finishes for CNC machining

CNC-machined parts as they emerge from the machine often exhibit visible tool marks, a feature

that may not align with your specific part requirements.

Fortunately, there exists a multitude of post-processing techniques aimed at enhancing the surface

appearance and elevating attributes such as wear resistance, corrosion resistance, and chemical

resistance.

Methods like anodizing, bead blasting, and powder coating present viable options for refining the

final presentation of your custom parts, allowing you to achieve the desired surface quality and

performance characteristics.

| Surface Finishes | ||

| Name | Applicable to | Machining marks |

| As machined | Metals, Plastics | Visible, light surface scratches |

| Smooth machining | ||

| Fine machining | Metals | Slightly visible |

| Polishing | Metals | Removed on primary surfaces |

| Bead blasting | Metals | Removed for non-cosmetic, removed on primary surfaces for cosmetic |

| Brushing | Metals | |

| Anodizing Type II | Aluminum | |

| Anodizing Type III | Aluminum | Visible under anodizing |

| Black oxide | Copper, Stainless steel, Alloy steel, Tool steel, Mild steel | Visible |

| Powder coating | Metals | Removed |

| Brushed + electropolishing | Stainless steel | Removed on Primary surfaces |

CNC Machining Applications

CNC milling machines play a crucial role in the manufacturing process across various industries.

These advanced machines are employed for crafting products from an array of materials, including

glass, metal, plastic, wood, and specialized components.

Skilled machinists utilize CNC machining to create prototypes and final products for diverse sectors

such as aerospace, automotive, hardware startups, manufacturing, medical devices, robotics,

and beyond.

Company Profile

FAQ's

1. The cost of CNC machining a part depends on a range of factors, some of which are

listed below:

1. Material: The choice of material impacts costs, with some materials, like aluminum, being more

cost-effective to machine than others such as Inconel, due to considerations like tool wear and

cutting speeds.

2. Complexity: Parts with intricate features tend to be more

expensive to machine. The complexity

of surface shapes, for example, directly influences machining costs.

3. Tolerances: Tighter dimensional tolerances increase the cost of

CNC machining. It's crucial to

balance precision requirements with cost considerations to optimize overall expenses.

4. Surface Finish: Attaining mirror finishes necessitates

specialized tools and machining strategies,

contributing to increased machining time and associated costs.

5. Quantity: The production volume plays a significant role in cost

considerations. Low-volume

production tends to be more expensive per part, as initial setup and programming costs are

amortized over a smaller number of parts.

2. Why choose CNC machining?

The choice of CNC machining is characterized by its speed, precision, and versatility.

This manufacturing solution distinguishes itself by efficiently producing end-use parts across various

volumes, all without the necessity for significant investments in hard tooling or elaborate set-ups.

3. How does compare to other suppliers on price?

Making direct comparisons may be complex, but as a rule of thumb, We's prices are usually 25-45%

more economical for plastic injection mold tools and CNC machined/turned parts in comparison to

suppliers in North America and Europe.

4. How quickly can I get my parts?

With complete 2D and 3D CAD models, we can manufacture quality parts in just two weeks.

However, for more complex parts with special features, additional time may be required.

Request a quote for accurate lead times tailored to your project.

Shipping is primarily done via air freight, taking only a few days

from China to Europe or North America.