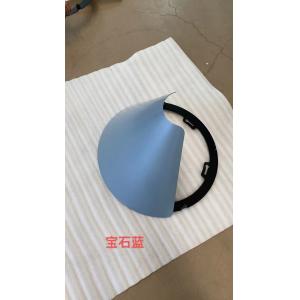

Product Details

OEM Aluminum Custom Metal Fabrication Lamp shade Part CNC Machining

Die casting is a manufacturing process used to produce metal parts

and components with high precision and repeatability. It involves

injecting molten metal into a mold cavity, known as a die, under

high pressure. Once the metal solidifies, the die is opened, and

the part is ejected. Die casting is commonly used for producing a

wide range of parts, from small and intricate to large and complex.

Here's an overview of the die casting process:

- Design: The process begins with the creation of a detailed 3D model of the

part to be produced. The design includes all necessary features,

dimensions, and specifications. Design engineers take into account

factors like draft angles, parting lines, and the location of

gating and ejector pins to facilitate the die casting process.

- Die Design and Fabrication: Once the part design is complete, the next step is to design and

fabricate the die, which is typically made of two steel halves. The

die must be able to withstand the high temperatures and pressures

involved in the process. It is machined to the exact shape of the

desired part, including any internal features.

- Mold Preparation: The die is installed in a die casting machine, which includes a

clamping unit to hold the die halves together and an injection unit

for introducing molten metal. The die is preheated to the

appropriate temperature to facilitate metal flow and prevent rapid

cooling that could cause defects.

- Injection: Molten metal, often an aluminum or zinc alloy, is melted in a

furnace and then injected into the die cavity at high pressure. The

pressure helps fill the mold quickly and ensures that the metal

reaches all parts of the cavity, including any intricate details.

- Cooling and Solidification: After injection, the molten metal rapidly cools and solidifies

inside the die cavity. The die is equipped with cooling channels to

control the cooling rate and prevent warping or cracking of the

part.

- Ejection: Once the metal has solidified, the die is opened, and ejector pins

or mechanisms push the part out of the mold. Any excess material,

known as flash, is also trimmed or removed at this stage.

- Finishing: The cast part may undergo secondary operations to remove any

remaining traces of flash, smooth rough surfaces, or achieve the

desired surface finish. These operations can include sanding,

machining, or tumbling.

- Quality Control: The finished cast parts are inspected to ensure they meet the

specified tolerances and quality standards. Dimensional

measurements, visual inspections, and material testing may be

performed.

- Reusing the Die: Die casting dies are designed for multiple cycles and can be

reused for many production runs. However, they may require

maintenance and refurbishment over time to ensure continued

accuracy and quality.

- Packaging and Shipping: Once inspected and approved, the cast parts are packaged and

prepared for shipment to customers or further assembly and use in

products.

Die casting offers advantages such as high dimensional accuracy,

excellent surface finish, and the ability to produce parts with

complex shapes. It is widely used in industries such as automotive,

aerospace, electronics, and consumer goods for producing a variety

of components, including engine parts, housings, and decorative

trim pieces.

| Brand | Chenyang |

| Our products | High-speed rail/ bullet train/ subway spare parts, Fitness/ massage

equipment spare parts, Wind power accessories, Automobile /

motorcycle spare parts, Solar street light spare parts,

Telecommunication and security equipment spare parts, Water filter

accessores, Plastic air filter spare parts, Fire Accessories etc,

such as Sheet plate series, Cabinet Series,Die casting series, CNC

machining series,Injection plastic series etc |

| Place of Origin | Qingdao China (Mainland) |

| Size | OEM Standard Size |

| Surface | Matte or gloss or upon clent's requirement |

| Process | Lasering, bending, welding, CNC machining, turining, milling,

grinding machining |

| Available Materials | AL:5052/5754/5082/5083/6061/6063/6082…. |

| ZL101/ZL102/ADC12… |

| Carbon Steel: Q235B/Q345E/Q345D/SPCC/SECC/DX51D/DX53D… |

| Stainless steel: 304/316/430/201... |

| Payment | T/T, L/C, Money Gram, Western Union |

| Delivery | Sample: 3~5 days for no mould items and 7~10 days for mould items |

| Mass goods: 15~20 working days |

Company Profile

Qingdao Chenyang Machinery MFG Co., Ltd. was established in May

2007, is a set of sheet metal, machining, die casting, spraying and

injection molding integrated production of high-tech enterprises.

The headquarters of the company is located in Yunshui 2nd Road of

the Automobile Industry New Town, with a construction area of

45,000 square meters, and the branch plant is located in Qingdao

Environmental Protection Industrial Park, with a construction area

of 12,000 square meters. The company has more than 200 employees,

including 45 management personnel and 27 middle and senior

technical R&D personnel. The company consists of sheet metal,

CNC processing department, die casting, injection molding four

industries, including sheet metal laser, bending, welding,

riveting, powder coating, painting, assembly and other departments.