Product Details

Fireproof And Lightweight Punched Aluminum Perforated Panel For

Safety & Security

- Application

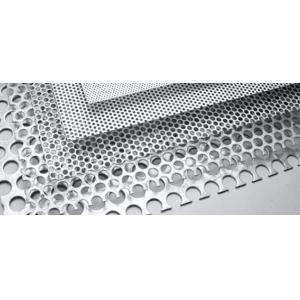

An aluminum punch hole panel, also known as a punched aluminum

panel or perforated aluminum panel, is a type of panel made from

aluminum that features a series of holes punched through its

surface. These holes are typically created using a punch press or a

similar mechanical method.

Aluminum punch hole panels offer similar advantages to perforated

panels, as mentioned in the previous response. Some of these

advantages include:

1,Lightweight: Aluminum is a lightweight material, making punch

hole panels easy to handle and install.

2,Durability: Aluminum is known for its corrosion resistance and

durability, making punch hole panels suitable for various indoor

and outdoor applications.

3,Aesthetic appeal: Punch hole panels can be designed with various

hole sizes, shapes, and patterns, allowing for customizable and

visually appealing designs.

4,Ventilation and airflow: The punched holes in the panel allow for

adequate ventilation and airflow, making them suitable for

applications where airflow and temperature control are important.

5,Acoustic properties: Depending on the hole size and pattern,

punch hole panels can help control sound and reduce noise levels by

absorbing and scattering sound waves.

6,Privacy and security: The hole size and pattern can be customized

to provide varying levels of privacy and security while still

allowing light transmission.

Aluminum punch hole panels find applications in architecture,

interior design, furniture manufacturing, automotive, electronics,

and other industries. They can be used for façades, sunshades,

partitions, ceilings, decorative screens, speaker grills, and more.

2.Product Parameters

| Perforated Aluminium Sheet |

| Aluminium Alloy | A1050,A1060,A1100,A3003,A3105,A5052,A5005, |

| Temper | H14,H16,H24,H26 ETC |

| Hope Shape | round,square ,oval,slot ,diamond ,triangle,rectangular

,rhombus,hexagonal,scale hexagonal or as per customer drawing |

| Thickness | 0.3-100mm |

| Hole Diameter | 0.3-10mm |

| Customerize size | standard size : 1x2m,3'x8',4x8'3x10',4'x10'

Size can be produced as per clients requirement |

| Hole Dia Pitch(mm) | Customized ,such as 5x10,3x5,10x15 etc |

| Surface Treatment | Mill finish ,Anodized ,powder coated ,PVDF coating, etc |

| Process | mold ,stamping ,leveling ,cutting ,bending ,reeling ,welding,

shaping ,cleaning and surface treatment |

| Quality Standard | ASTM B209,EN573-1 |

Located in Shenzhen, China

- Features Of Stainless Steel Sheet

- Accurate dimension

- Architecturally flat material

- Excellent service life

- Slit-edge

- 100% honor to the SS_grade in every sheet

- Advanced Production Equipment

- Strict Quality Control

- Skillful technology-Complete Surface Processing Technology

- Multiply way of manufacturing-Produce According to Customer's

Requirement

- Completely Industrial Production Process

- Large-scale Production Capacity-40000 Sqm Own Factory

- Provide SGS Test Report-Affirmed by Global Customers

- Reliable & Trusted Since 1994(26 years history)

SGS TEST REPORT COULD BE PROVIDED FOR YOUR REFERENCE!!

1- Cross section test

2-Adhesive power test

3-Salt spray test

4-Chemical resistance test

Company Profile

Found in 2019, Max Steel trading developed to be a stainless steel

high-tec company.

We focus on all kinds of metal products and project decoration.

Our product line includes Aluminum honeycomb panel Stainless steel

decorative sheet and customized metal works. They are widely use for High end hotel inner decoration, Luxury Shopping

Mall decoration and the other public places where need exclusive

metal products.

With more than 20 years jobsite engineering practice experience,

Maxsteel team will discuss and study every case with our customers,

we wish our professional suggestion can bring the value to both us,

like creating the marketable metal product, improving the effective

communication, building stable relationship between us.

About Maxsteel.pdf

Thank you!