Add to Cart

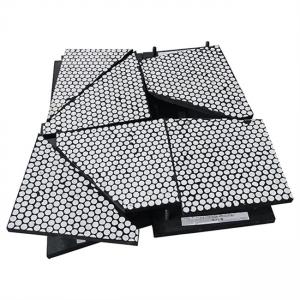

Customized wear rubber ceramic liners ceramic tiles products wear

liner chute

Ceramic Wear Liner Description:

A ceramic wear liner is typically made of high-quality ceramics,

such as alumina, zirconia, or silicon carbide, that offer excellent

resistance to wear, impact, and high temperatures.

Ceramic Wear Liner Specification:

Dimension ( L×W×T) | Thickness details | ||

300*300*12mm | 6mm ceramic +6mm rubber | ||

250*250*15mm | 10mm ceramic +5mm rubber | ||

250*300*16mm | 12mm ceramic +4mm rubber | ||

500*500*15mm | 10mm ceramic +5mm rubber | ||

500*400*20mm | 12mm ceramic +8mm rubber | ||

500*500*30mm | 20mm ceramic +10mm rubber | ||

300*300*63mm | 50mm ceramic +13mm rubber | ||

500*500*63mm | 50mm ceramic +13mm rubber |

Ceramic Wear Liner Features:

1. excellent impact resistant

2. excellent wear resistant

3. excellent sound noise solution

4. extend the service life of equipment

5. cost effective

6. reduce maintance and downtime

7. customization accept

8. rich experiences and strict QC ensures high quality

Ceramic Wear Liner Application:

Ceramic wear liners are commonly used in industrial applications to

protect equipment and surfaces from abrasive or corrosive

materials. They can be applied to chutes, hoppers, conveyor

systems, and other areas where material flow causes wear and tear.

Ceramic wear liners offer excellent resistance to high

temperatures, impact, and abrasion, making them ideal for use in

mining, cement, steel, and power generation industries.

Why choose us:

1. Rich experience on production process of ceramic wear liner

2. Strict quality control on rubber ceramic wear liner

3. Good delivery time

4. Custom shape rubber ceramic wear liner are available.

5. Excellent bonding between rubber and ceramic

We are a factory dedicated to producing ceramic wear liner and have

been improving the properties of ceramics. We use high quality

rubber to offer better impact resistance and high quality rubber

can also help holding the ceramic tiles, no ceramic tiles falling.