Add to Cart

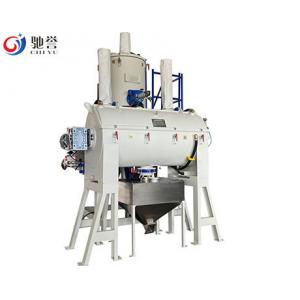

PVC Powder Mixing Machine With Feeding System And Big Bag Loading Unit

PVC Technologies Mixing, Feeding, Dosing Systems

We are one of the major leading manufacturers of PVC Mixer machines, PVC Dosing systems,Feeding systems and Auxiliary equipment for PVC sector since 2004. ChiYu Company have gained an outstanding reputation in many countries with considering about customers demands since establishment, evidence of this is that we have great references from many companies all around the world. Additionally we produce equipments and accessories with the PVC mixer machines for the variety of companies which uses PVC Meterials.

Chiyu Automation company offering dosing systems of the raw materials, compatible and ideal automation process for production line and different capacities according to its customers budgets and needs.Dosing systems weigh the PVC formulation automatically in desirable ratio by load cell very precisely and transfer them into feeding silos.The automation process of this system could be watched and controlled through PLC control monitor.The ratio of PVC formulation which is used in production could be changed and rearranged by the buttons on the operator panel.

1.Maximum capacity and efficiency

2.Saving from time

3.Save handwork

4.Additives used in each product provides the same rate and ensures the continuity of product quality.

5.Reduce waste

We are offering dosing systems of the raw materials, compatible and ideal automation process for production line and different capacities according to its customers budgets and needs….

Big Bag Discharge Station

Hoppers are used primarily for handling raw material and product as storage vessels as

well as transporters, and feeders for different stages of the processes. Types of hopper, conical produced from stainless steel or steel with anti

corrosion paint and come in a variety of sizes depending of the requirement.

Raw Materials Storage Silo

In production for providing the desired process in the purpose of storing and holding capacity from 5 to 30 m3 volume of the raw materials storage silos are operative. Raw material storage silos can be manufactured from black metal and stainless steel, assembly and design by our factory. Dimensions and diameters of the silos are designed and produce according to the capacity of the production (client factory) and size of the area to be established. In production of materials with intensive calcite to provide easier drain vibro-motor of adequate power is used.

Technical data:

| Type | Total capaicty litres | Weight per batch kgs | Motor power KW |

| SHR10 | 10 | 5 | 5 |

| SHR50 | 50 | 25 | 11 |

| SHR100 | 100 | 60 | 15 |

| SHR200 | 200 | 100 | 75 |

| SHR300 | 300 | 150 | 90 |

| SHR500 | 500 | 200 | 90 |

| SHR800 | 800 | 300 | 160 |

| SHR1000 | 1000 | 250 | 200 |

| SHR1500 | 1500 | 450 | 250 |

| SHR2000 | 2000 | 900 | 560 |