Add to Cart

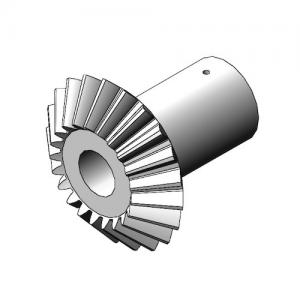

OEM Cast Iron Helical Gear Iron Casting Gear For Farming Equipments

Quick Detail:

· Grey Iron Casting Helical Gear

· Cast iron

· Resin Sand Casting and CNC Machining

· Shot Blasting fininsh for surface treatment

· Farm Machinery

Product Description:

A cast iron helical gear refers to a helical gear that is made from

cast iron material. Cast iron is a common material used in gear

manufacturing due to its excellent strength, durability, and wear

resistance. When combined with the helical gear design, it creates

a cast iron helical gear.

The term "cast iron" refers to a group of iron-carbon alloys with a

carbon content greater than 2%. Cast iron is known for its high

hardness, good machinability, and ability to withstand heavy loads

and high temperatures. These properties make it suitable for

various industrial applications, including gear manufacturing.

Cast iron helical gears offer several advantages. They have high

strength and can handle heavy loads, making them ideal for

applications that require transmitting substantial power. The

hardness and wear resistance of cast iron contribute to the gear's

durability and longevity. Additionally, cast iron has good damping

properties, which helps reduce noise and vibration during gear

operation.

The manufacturing process for cast iron helical gears typically

involves casting the molten iron into a mold with the desired gear

shape. After casting, the gear undergoes machining processes to

achieve the final dimensions and tooth profile.

It's important to note that while cast iron helical gears have

their advantages, the specific choice of gear material depends on

the application requirements, such as load, speed, and operating

conditions. Other materials like steel alloys or non-metallic

materials may also be used for helical gears, depending on the

specific needs of the gear system.

Product Specifications:

| Commodity | Iron Casting & Machining Parts / Gear Cap |

| Standard | ASTM, DIN, JIS, EN, ISO, BS, JCSI, GB |

| Material | Grey iron (HT200,HT250,HT300), Ductile iron (QT400-18,QT400-15,QT450-10,QT500-7) |

| Unit Weight | 0,05 kg ~ 1,000 kg. |

| Tolerance | CT6-CT8 |

| Machining | Turning, Milling, Drilling, Cutting, Reaming, Threading, Welding, Tooling, etc |

| Surface Treatment | Shot blasting, Painting, Powder coating, Electroplating, Chrome plating, etc |

| Package | Standard wooden box package or as your customized package |

| Applications | Agricultural machinery, Petroleum machinery, Mining machines, Construction, Automotive & Truck, Medical, Marine, Railway & Train, Power lines, Furniture, Lighting, Flange, Valve and Pump, Electronic, Pipeline, etc. |

| Brand | Twinkle Industrial |

Product Applications:

Widely used agricultural machinery, petroleum machinery, mining

machines, construction, automotive & truck, medical, marine,

railway & train, power lines, furniture, lighting, flange,

valve and pump, electronic, pipeline, etc.

FAQ

Q1. How can we get a quotation?

A: Please send the parts 2D drawing (in PDF format) and 3D model in

IGS or STP format together with material, production technique,

purchasing qty, etc, or provide sample to us.

Q2. What about the lead time?

A: 15-20 days for Sample making ,20 working days for mass

production.

Q3. Do you have any MOQ limit for casting parts?

A: It depends on different parts. For some parts, 1 pc can be

acceptable.

Q4. What is your payment term?

A: Mold: 50% payment in advance, balance after the sample approval.

B: Mass production: 30% payment in advance, 70% balance before

shipment.

Q5. What is your quality control process?

A: Each casting parts will be provided with raw material report (

chemical composition and physical property), and dimension

measuring report before shipment.

Q6. How about the packaging?

A: Standard wooden box package or as your customized package.