Add to Cart

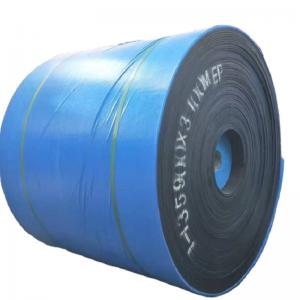

Black Heat-resistant conveyor belt ST2000 Special Conveyor Belts

1. Concept

The heat-resistant conveyor belt [1] is made of multi-layer rubber

cotton canvas (polyester cotton cloth) or polyester canvas covered

with high-temperature or heat-resistant rubber and bonded together

by high-temperature vulcanization. It is suitable for conveying hot

coke and cement below 175°C. , Slag and hot castings, etc.

Type I: It can withstand test temperature not greater than 100℃,

the highest short-time operating temperature is 150℃, code T1.

Type Ⅱ: It can withstand the test temperature of not more than

125℃, the maximum short-time operating temperature is 170℃, and the

code is T2.

Type Ⅲ: It can withstand the test temperature of not more than

150℃, the highest short-time operating temperature is 200℃, and the

code is T3.

Type IV: Can withstand test temperature not greater than 175℃,

maximum short-time operating temperature 250℃, code T4.

2. Maintenance method

Conveyor belts should be kept clean during use and storage, avoid

direct sunlight or rain and snow, prevent contact with acids,

alkalis, oils, organic solvents and other substances, and be one

meter away from heating devices.

During storage, the warehouse temperature should be kept between

18-40 ℃, and the relative humidity should be kept between 50-80%.

During the storage period, the conveyor belt must be placed in a

roll, and must not be folded. During the storage period, it should

be turned once every season.

Conveyor belts of different types and specifications are not

suitable to be used together, and the joints should preferably be

glued.

The type, structure, specification and number of layers of the

conveyor belt should be selected reasonably according to the

conditions of use.

The running speed of the conveyor belt should generally not be

greater than 2.5 m/s. For materials with large lumps and abrasion

and the use of fixed unloading devices, the speed should be as low

as possible.

The relationship between the diameter of the transmission roller of

the conveyor and the cloth layer of the conveyor belt, the matching

of the transmission roller and the reversing roller, and the

requirements for the groove angle of the idler should be selected

reasonably according to the design requirements of the conveyor.

The feeding direction should follow the running direction of the

conveyor belt. In order to reduce the impact on the conveyor belt

when the material falls, a chute should be used to reduce the

material falling distance; the conveyor belt receiving section

should shorten the distance between the rollers and use the buffer

roller as leakage , The belt conforms to adopt a soft and moderate

baffle to prevent the baffle from being too hard and scratching the

belt surface of the conveyor belt.

<

| Variety | Standards and main indicators |

| Ordinary steel cord conveyor belt | GB/T9770-2001 |

| Flame-retardant steel cord conveyor belt | MT668-1997 |

| General flame-retardant steel cord conveyor belt | MT668-1997 |

| Heat-resistant steel cord conveyor belt | HG2297-92 |

| Wear-resistant steel cord conveyor belt | Shaoboer wear amount ≤90mm 3 |

| Acid, alkali and oil resistant steel cord conveyor belt | HG4-846 HG4-846 |

| Cold-resistant steel cord conveyor belt | Brittleness temperature -40℃ |