Product Details

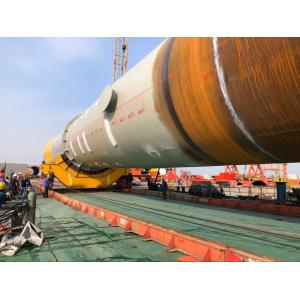

Steel structure for offshore and onshore wind power generator

The wind power tower is the supporting piece of the wind power

generation system, which is used to support the wind generator and

resist the vibration of wind generator.

Manufacturing wind turbines, especiallly the supporting tower, uses

a substantial amount of welding equipment. Welding procedures and

consumables can vary based on tower requirements for height,

design, and location.

Towers, typically made from carbon steel, consist of three or four

fabricated sections each three to five meters in diameter and up to

40 m long. The sections are fabricated out of smaller, individually

rolled cylindrical pieces – called cans – which are then welded

together with multi-pass butt welds made by submerged arc welding.

Smaller can sections are welded on a large assembly line, called a

growing line. After assembling the sections, they are transported

to the installation site, lifted into place, and bolted together.

Welding requirements for offshore tower construction are impacted

by the tower’s large size and associated nacelles, as well as the

thicker steel required for strength and fatigue resistance. Joining

thicker steel sections with larger weld joints requires using a

greater volume of welding consumables, thus requiring additional

welding passes. This adds time and cost to the job.

Feature

| product | wind power tower |

| painting | HEMPEL |

| color | yellow |

| material | high quiality steel |

| application | offshore and onshore |

| welding test | NDT |

| steel working | welding and inspected |

| process | rolled |

Manufacturing process

1, material cutting

2. steel plate rolling and welding

3. welding

4. NDT test

5. paint inspection

6. testing and inspection instrument

7. wind turbine tower transfer and shipment

Company Profile

1.Brief Introduction—Bulk material conveying and service

professional supplier

Shanghai Sunshine Industrial Technology is specialized in bulk

material handling equipment, integrator and overseas agent of bulk

material handling. Sunshine Industrial Technology takes the

development of precision manufacturing capacity as its strategic

goal, specializes in manufacturing large and medium-sized precision

parts and reliable bulk material conveying equipment . In addition,

we provide variety of solutions and equipment to clients based on

requirement, including EPC, spare parts, consulting and design

services. Our major product including load and unload equipment

(train tipping machine system, ship unloader, ship loader etc),

conveying equipment (belt conveyor, screw conveyor, bucket conveyor

system, scraper conveyor system, dense phase pneumatic conveying

system), storage equipment (bucket wheel reclaimer, scraper

reclaimer, cranes and all kinds of grab bucket), screen equipment,

auxiliary equipment.

In order to meet the client`s requirement, and provide

comprehensive products and service in bulk material handling. We

had signed a contract with bulk material handling equipment

manufacturer leading company of China Huadian Caofeidian heavy

industry equipment Co., Ltd ,in charge of the overseas market and

project investment of Huadian Caofeidian heavy industry equipment

Co., Ltd;Reaching an agreement in charge of the overseas market of

Liaoning Zhigu mining equipment Co., Ltd ;Zhejiang Xiangshan

Guangming Belt conveyor factory and Wuxi Yixiang machinery Co.,

Ltd.

To be sincere and keep moving, Shanghai Sunshine industrial

technology Co., Ltd always dedicate to high quality products and

service!

2.Organization structure

3.Maine product and technical consulting

4.qualification documents

Qualification documents of authorized units in overseas markets

Qualification documents of authorized units in overseas markets

5.Production equipment and facilities

6.Production product display