Add to Cart

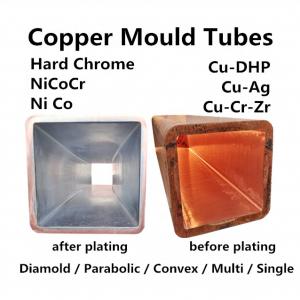

Strong and durable High mechanical stability Continuous Casting Mould Tube for Con cast machine

Function of Mould Copper Tube-Characteristics of Mould Copper Tube

Mold copper tube plays a very important role in industrial

production. For example, die copper tubes are used in the

manufacture of ships, ships, automobiles and refrigerators. The

main characteristics of copper tube material for high efficiency

continuous casting mold are: high thermal conductivity, high

recrystallization temperature, thermal fatigue resistance, high

strength, good wear resistance and long service life. The main

characteristic of copper tube material for high efficiency

continuous casting mold is the best comprehensive performance.

The characteristics of explosion forming mould copper pipe are that

the conical mould copper pipe can be molded by inner core and outer

mold or molding. Replication will destroy the microstructure of

copper and affect its service life. Processing complex taper

requires special processing equipment, which increases the

manufacturing cost. Pressure forming will lead to large head

cutting and tail cutting, and the output of copper is low. The

explosion formed mold copper tube can be made into an inner cavity

with multi taper and small fillet, which is especially conducive to

the repair of waste molds.

Function of Mould Copper Tube-Performance of Mould Copper Tube

In order to improve the wear resistance of the chromium plating

layer and prolong the service life of the mold copper pipe, a

nickel cobalt alloy coating with a thickness of 0.4-0.5mm is added

between the inner surface of the mold copper pipe and the chromium

plating layer as the transition layer. Therefore, it is called

nickel cobalt alloy hard chromium coating. Composite copper plated

pipe for short. The metal content is as follows: the coating

hardness is 300-600hv.

Nickel cobalt alloy coating has good chemical corrosion resistance,

heat corrosion resistance and wear resistance. It not only prevents

the diffusion of zinc, sulfur and cadmium.

Parameters

| Copper Mould Tube | Size (mm) | Thickness (mm) | Length (mm) | Radius (mm) | Design or Taylor-Made |

| ODM & OEM | |||||

| Billet Square | 50x50 - 680x680 | 6 - 80 | 600 - 1250 | 3000 - 17500 | Exactly follow your drawing and requirement |

| Copper Mold Tubes | or straight | ||||

| Bloom Rectangle | 50x50 - 680x680 | 10 - 80 | 600 - 1250 | 3000 - 17500 | Exactly follow your drawing and requirement |

| Copper Mould Tubes | or straight | ||||

| Slab Copper Mold Tube | 50x50 - 680x680 | 6 - 80 | 600 - 1250 | 3000 - 17500 | Exactly follow your drawing and requirement |

| or straight | |||||

| Beam Blank Mould Tube | 550-150 x 120-70 | 12 - 80 | 600 - 1250 | 3000 - 17500 | Exactly follow your drawing and requirement |

| or straight | |||||

| Round Mould Tubes | φ110 - φ1850 | 10 - 80 | 600 - 1250 | 3000 - 17500 | Exactly follow your drawing and requirement |

| or straight | |||||

| Non-Standard | 550-150 x 120-70 | 12 - 80 | 600 - 1250 | 3000 - 17500 | Exactly follow your drawing and requirement |

| Copper Mold Tube | or straight |

Application

The copper mould tube is widely used in steel continuous casting machines. The main function of copper mould tube is to solidify the molten steel to the required size and shape.

Q1. What is the advantage about your company?

A1. We have professional team and professional production line.

Q2. Why should I choose your products?

A2. Our products are high quality and low price.

Q3.Can your company provide any other service?

A3. We can provide good after-sale and fast delivery.