Add to Cart

Technical Parameters

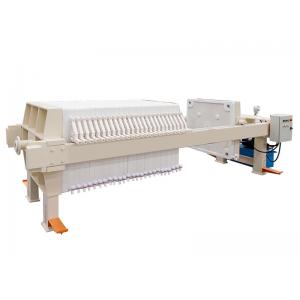

Model: ZR40-630-30U

Filter area: 40m2

Filter plate size: 700*700mm2

Filter cake thickness: 30mm

Filter room volume: 595L

Filter plate quantity: 49pcs

Motor power: 2.2kw

Filter pressure: 0.8Mpa

Technical Parameter Of ZR Serial

| Model | Filter area (M2) | Plate size (mm) | Cake thickness (mm) | Room volume (L) | Plate qty (Pcs) | Motor Power (Kw) | Filter pressure (Mpa) | Whole weight (Kg) | Outline dimension (L*W*H)(mm) | Foundation size (mm) | ||||

| L | B | D | H | C | ||||||||||

| ZR10-630-30U | 10 | 700*700 | 30 | 154 | 12 | 2.2 | 0.8 | 1880 | 1880*1115*1130 | 1760 | 400 | 1115 | 780 | 495 |

| ZR15-630-30U | 15 | 226 | 18 | 2080 | 2950*1115*1130 | 2060 | ||||||||

| ZR20-630-30U | 20 | 298 | 24 | 2280 | 3250*1115*1130 | 2360 | ||||||||

| ZR25-630-30U | 25 | 375 | 31 | 2500 | 3600*1115*1130 | 2710 | ||||||||

| ZR30-630-30U | 30 | 452 | 37 | 2700 | 3900*1115*1130 | 3010 | ||||||||

| ZR40-630-30U | 40 | 595 | 49 | 3100 | 4500*1115*1130 | 3610 | ||||||||

| ZR20-800-30U | 20 | 870*870 | 307 | 15 | 2800 | 2940*1300*1300 | 2070 | 500 | 1300 | 865 | 505 | |||

| ZR30-800-30U | 30 | 460 | 23 | 3100 | 3380*1300*1300 | 2510 | ||||||||

| ZR40-800-30U | 40 | 595 | 30 | 3400 | 3770*1300*1300 | 2900 | ||||||||

| ZR50-800-30U | 50 | 748 | 38 | 3700 | 4210*1300*1300 | 3340 | ||||||||

| ZR60-800-30U | 60 | 902 | 46 | 4100 | 4630*1300*1300 | 3760 | ||||||||

| ZR70-800-30U | 70 | 1056 | 54 | 4500 | 5090*1300*1300 | 4220 | ||||||||

| ZR80-800-30U | 80 | 1210 | 62 | 5000 | 5530*1300*1300 | 4660 | ||||||||

| ZR50-1000-30U | 50 | 1000*1000 | 752 | 28 | 4 | 4320 | 3880*1450*1450 | 2900 | 600 | 1450 | 940 | 520 | ||

| ZR60-1000-30U | 60 | 908 | 34 | 4730 | 4430*1450*1450 | 3540 | ||||||||

| ZR70-1000-30U | 70 | 1063 | 40 | 5170 | 4600*1450*1450 | 3710 | ||||||||

| ZR80-1000-30U | 80 | 1219 | 46 | 5580 | 4960*1450*1450 | 4070 | ||||||||

| ZR100-1000-30U | 100 | 1509 | 57 | 6400 | 5890*1450*1450 | 4850 | ||||||||

| ZR120-1000-30U | 120 | 1816 | 69 | 7200 | 6590*1450*1450 | 5550 | ||||||||

| ZR100-1250-30U | 100 | 1250*1250 | 1519 | 36 | 5.5 | 8300 | 5040*1770*1600 | 3920 | 800 | 1770 | 980 | 435 | ||

| ZR120-1250-30U | 120 | 1806 | 43 | 9000 | 5490*1770*1600 | 4370 | ||||||||

| ZR140-150-30U | 140 | 2153 | 51 | 9700 | 6010*1770*1600 | 4890 | ||||||||

| ZR160-1250-30U | 160 | 2422 | 58 | 10400 | 6470*1770*1600 | 5350 | ||||||||

| ZR180-1250-30U | 180 | 2710 | 65 | 11100 | 6920*1770*1600 | 5800 | ||||||||

| ZR200-1250-30U | 200 | 2997 | 72 | 11800 | 7380*1770*1600 | 6260 | ||||||||

| ZR220-1250-30U | 220 | 3326 | 80 | 12500 | 7900*1770*1600 | 6780 | ||||||||

| ZR250-1250-30U | 250 | 3778 | 91 | 14000 | 8610*1770*1600 | 7600 | ||||||||

| ZR200-1500-30U | 200 | 1500*1500 | 3030 | 49 | 0.6 | 20000 | 6370*2000*1920 | 5070 | 1000 | 1970 | 1170 | 505 | ||

| ZR250-1500-30U | 250 | 3739 | 61 | 22500 | 7170*2000*1920 | 5920 | ||||||||

| ZR300-1500-30U | 300 | 4413 | 74 | 25000 | 8270*2000*1920 | 6880 | ||||||||

| ZR350-1500-30U | 350 | 5210 | 86 | 27500 | 9110*2000*1920 | 7700 | ||||||||

| ZR400-1500-30U | 400 | 6007 | 99 | 30000 | 10200*2000*1920 | 8600 | ||||||||

| ZR450-1500-30U | 450 | 6743 | 111 | 33000 | 10930*2000*1920 | 9450 | ||||||||

| ZR500-1500-30U | 500 | 7478 | 123 | 36500 | 11480*2000*1920 | 10580 | ||||||||

| ZR600-2000-40U | 600 | 2000*2000 | 40 | 12000 | 83 | 49000 | 10615*3000*2500 | 8980 | 1200 | 2600 | 1500 | 505 | ||

| ZR700-2000-40U | 700 | 14000 | 97 | 53000 | 11765*3000*2500 | 10130 | ||||||||

| ZR800-2000-40U | 800 | 16000 | 111 | 57000 | 12915*3000*2500 | 11280 | ||||||||

| ZR900-2000-40U | 900 | 18000 | 125 | 61000 | 14060*2000*2500 | 12425 | ||||||||

| ZR1000-2000-40U | 1000 | 20000 | 139 | 65000 | 15210*2000*2500 | 13575 | ||||||||

Profile

The compression filter press consists of membrane plates (the membrane plate is composed of two polypropylene membranes and a high strength polypropylene core plate with heat capacity) and van filter plates arranged together to form filter chambers. Under the pressure of the feed pump, the slurry is input into the filter chamber. The solid in the slurry is separated from the liquid by the filter cloth. When the solids in the slurry forms a cake, the air is put into the diaphragm, and the solid in the filter chamber is fully pressed. Reduce moisture content. The machine has its unique characteristics especially for the filter of viscous material and users with higher water content requirements.

Working Principle Of Chamber Filter Press

1. Slurry is pumped into the filter press. The solids are

distributed evenly on the filter cloths during the feed (fill)

cycle.

2. Solids begin to build on the filter cloth, trapping the ensuing

particles and building a filter cake. The filter cake acts as a

depth filter for solid/liquid separation. Filtrate exits the plates

through the corner ports into the manifold.

3. When the correct valves in the manifold are open, the filtrate

exits the press through the filtrate outlet. As the filter press

feed pump builds pressure, the solids build within the chambers

until they are completely full of filter cake.

4. Once the chambers are full, the fill cycle is complete and the

filter press is ready to be emptied.