Add to Cart

Beer Fermentation Dimple Jacketed heat exchanger for Tank OEM Manufacturer

Working principle

The plate heat exchangers are made of stainless steel and are ideal

for the indirect heating and cooling of process liquids in plants

or tanks. They are manufactured to the specific requirements of

each customer. They transfer the thermal energy between the heat

exchanger medium that flows through the heat exchanger and the

process liquid.

The process liquid in the container circulates around the plate

heat exchanger and is heated up to the desired working temperature

and maintained. If heat is generated in a process (for example by a

rectifier or an exothermic reaction), this can be cooled down by

the heat exchangers. For heating applications hot water, steam,

saturated steam and thermal oil can be used as a heat exchanger

medium. Water, salt solutions and glycol are suitable for cooling.

Process Type

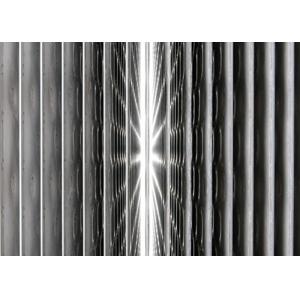

1. Two sheets of steel are overlapped and welded by laser. Laser

ring welding is used in the middle of the sheet and two laser

welding seals are used around the edge.

2. Injecting high-pressure liquid between plates makes the plates

expand and deform under pressure, forming a hollow plate heat

exchanger with uneven surface.

Features

1. Available in most materials, like stainless steel 304, 316L,

2205 and titanium

2. High operating pressures

3. High operating temperatures

4. No gaskets required

5. Corrosion resistant

6. Easily formed to fit the shape you need

7. Cutouts are easily provided

8. Thermally efficient types of heat transfer

9. Immersion heating and cooling.

10. Clamp-on heating, cooling, and temperature maintenance

11. Integral jacketing for heating and cooling

12. Custom heat exchanger design

Technical parameters

| Product Name | Pillow plate heat exchanger |

| Material | Stainless Steel |

| Color | Nickel White |

| Standard | DIN GB ISO JIS BA ANSI ASMI |

| Grade | SUS201,SUS304,SUS316,DSS2205 |

| Overview double pillow embossed plate material ratios | Pillow plate 0.8mm+0.8mm pillow plate 1.0mm+1.0mm Pillow plate1.2mm+1.2mm Pillow plate1.5mm+1.5mm Pillow plate2.0mm+2.0mm |

| Overview single pillow embossed plate material ratios | Pillow plate 0.8 mm + 2.0 mm base plate pillow plate 1.0 mm + 2.5 mm base plate pillow plate 1.2 mm + 4.0 tot 15 mm base plate pillow plate 1.5 mm + 4.0 tot 15 mm base plate pillow plate 2.0 mm + 5.0 tot 15 mm base plate |

Application

1. Wide-channel plate-shell heat exchanger:

Specially designed for working conditions with larger particles or

higher viscosity, the medium can fully flow in the runner

without blockage under the above working conditions. Generally, the

solid medium goes between the plates without contacts, and the

clean medium goes through the plate cavity with contacts:

Flow resistance is small and scaling is not easy.

High heat transfer coefficient.

Easy to clean.

2. Plate heat recovery unit:

It is a special case of plate and shell heat exchanger, which is

used to recover various waste steam and waste heat.

3. Chill System:

Used as evaporator in refrigeration system

Falling film ice water machine

Large Slip Ice Maker

Processing equipment

Tips:welded pillow plate;plate heat exchanger beer;cooling pillow plate