Add to Cart

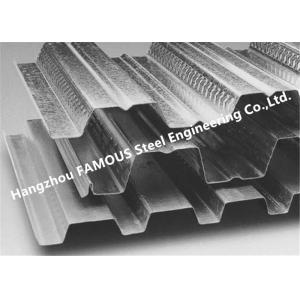

Durability Corrugated Metal Floor Decking for Slab Construction

The metal floor decking is made of galvanized steel sheet by roll forming, and its cross section is V-shaped, U-shaped, trapezoidal or similar. It is mainly used as a permanent template and can also be selected for other purposes. Products are widely used in power plants, power equipment companies, automobile exhibition halls, steel structure workshops, cement warehouses, steel structure offices, airport terminals, railway stations, stadiums, concert halls, grand theaters, large supermarkets, logistics centers, Olympic venues. Steel structures such as venues. Adapting to the requirements of rapid construction of the main steel structure, it can provide a firm working platform in a short time, and can use multiple floors to lay the profiled steel plate and layer the concrete flow of the concrete slab.

Specifications:

| Name | Durability Corrugated Metal Floor Decking for Slab Construction |

| Base material | Steel Sheet |

| Steel Grade | SGCC |

| Yield strength | Q235 or Q345 Refer to Standards GB/T1591-2008 |

| Thickness | 0.8 -1.5mm(normal 0.8,1.0,1.2) |

| Zinc coating | 60-275g/m2 |

| Wave Height | 51mm-76mm |

| Effective Width | 688mm-940mm |

Length | 0-11.8m |

| Less than 5.8m load in 20GP | |

| 5.8m-11.8m load in 40GP | |

| Packing | Bundle ,water-proof package with steel belt |

| Delivery time | 20 days after confirmation |

Following are some of typical profiles available in market:

| Closed type galvanized steel floor decking | YXB51-200-600 |

| YXB65-186-558 | |

| YXB60-253-760 | |

| YXB60-180-540 | |

| YXB51-200-600 | |

| YXB65-186-558 | |

| (2) Opened type galvanized steel floor decking | YX75-230-690 |

| YX75-200-600 | |

| YX38-152-915 | |

| YX51-305-915 | |

| YX76-305-915 | |

| YX75-230-690 | |

| YX75-200-600 | |

| YX51-250-750 | |

| YX51-335-1005 | |

| YX76-344-688 | |

| (3) swallow tail galvanized steel floor decking | YX51-200-600 |

| YX51-190-760 | |

| YX51-200-800 | |

| YX51-200-600 |

Advantages:

Greater Durability

The FAMOUS steel base product has a Z350 zinc-coating mass. It was

selected to provide superior corrosion protection in service,

directly as a result of increased coating mass. FAMOUS steel is

also available with a Z450 coating mass with a 15 year warranty.

Comprehensive shear stud welding tests across a range of base

thickness with both coating masses were undertaken to ensure

consistent results can be achieved on site.

Unbeatable Strength

Steel and concrete composite slabs are lighter and stronger than

most conventional slabs. The steel decking provides tensile

reinforcement, combining with the compressible strength of the

concrete for an all round stronger slab. Steel decking profiles are

designed to prevent any longitudinal slip between the steel and

concrete in the slab itself, and any transverse movement between

the slab and supporting beams.

Greater Savings

The weight savings achieved in composite slabs can be passed on to

other areas of the design, such as foundations. And because steel

decking acts as permanent formwork, it can significantly reduce the

need for propping or temporary formwork -saving both time and

money.

Easy On-Site Handling

Steel decking is delivered to site in pre-cut lengths, and in

pr-packaged bundles. The bundles can be easily craned into work

areas, and the individual sheets quickly layed by hand. One truck

can carry 1,000 sq meters of decking at a time, and a team can

install up to 400 sq meters in a day.

Speedy, Safe Construction

A composite slab effectively acts as a safe working platform. Once

the slab is poured, following trades can get on with their jobs

below almost immediately. At the same time, work can continue

unhindered on the floors above, allowing simple installation of

services. Cable trays, duct-work and service pipes can be suspended

neatly underneath the slab with purpose designed clips, brackets

and hangers that locate easily and quickly into recesses in the

steel decking profile.

To complete our floor decking products we advise a complete floor slab construction by adding the supply and laying of reinforced concrete. This single point solution allows a fully integrated metal deck and concrete slab with associated trade interface and program advantages.

Composite slab which is comprised of lightly reinforced concrete cast on profiled steel decking are an option whether the beams are down-stand or integrated within the slab depth for a shallow floor form of construction. The slabs are normally reinforced using an upper layer of mesh and, sometimes additional bars in the troughs (usually for longer periods of fire resistance and heavy loads). Fiber reinforcement may also be used. Spans of up to 4.5 m can be achieved using trapezoidal decking. Some so-called deep decking profiles also exist (over 200 mm deep), that can span 6 m or so without propping during construction.

While FASEC Rebar-truss triangle welded metal decking system adapts rapid construction requirements of the main steel structure and provide fast work procedures. It can save a lot of construction time compared to traditional floor decking system. It can also improve the rigidity of the floor and save the amount of steel and concrete, so as to reduce the project budget.

The Surface embossed increase the bonding of floor deck and concrete, make the floor deck system has high-strength bearing capacity. It is totally fire-proof and can span long without middle propping.

So from cost saving and time saving view, the FASEC rebar-truss triangle welded metal decking system is better choice. However, in much of ready design, the deck is already designed and in avoiding of redesign, recalculation and re-submit/approval, we can also offer various customized steel floor deck profiles to cater for various contractors’ need, meanwhile we will offer various technical support in the aspects of load span and stress analysis etc.