Product Details

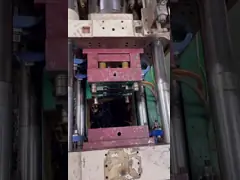

China OEM Foundry Aluminum / Zinc Die Casting Mould For Table Leg

Part

Packaging & Delivery

| Packaging Detail: | ensure the products will not be damaged during transportation |

| Delivery Detail: | negotiation |

Specifications

aluminum table leg (table legs)

process: casting

finishing: painting or electroplating

size: diameter 700mm.

Aluminum table leg, zinc table leg, plastic table leg

We provide various steady quality table legs, the material can be

aluminum, zinc or plastic.

We open new mould of table legs and manufacture metal table legs or

plastic table leg by our casting machines.

Aluminum die casting (tooling die casting, mold die casting):

Machinery parts & accessories die casting

Auto parts and accessories die casting

Heat sink die casting

LED lamp parts and accessories (lamp cup, lamp holder, lamp

shade...)

Other light fittings & fixture die casting

Furniture accessories & parts die cast

Electromotor parts and accessories die casting

Instrument parts and accessories die casting

Metal hand wheel die casting

Other aluminum & zinc parts die cast

Aluminum mould, zinc alloy mould, aluminum die cast parts, zinc die

cast parts.

Company Profile

Company Information:Founded in 1993, WeiYU Precision Mould Factory

is a leading professional experienced manufacturer of plastic

injection mold in China.

Our professional staff are mastered of tool/mold making service

including plastic injection mould, die casting mould, blow mold and

metal stamping mold (die), At the same time our business category

is also involved in molded part producing such as plastic parts,

castings parts, plastic & metal over-mould parts, stamping

parts, rubber parts, and precision machined parts.

With self-built plant, the company enjoys a convenient

transportation, only ten minutes drive from the entries of

Dongguan-Shenzhen Expressway and Guangzhou-Shenzhen Expressway.

Our business philosophy is advancing with the times. The latest

software systems such as CAD, UG and PRO/E SOLID WORKS are applied

to the engineering design, which greatly help optimize the mould

designing. Additionally, high precise CNC, CNC EDM and other

advanced machines are well equiped in our plant. All of these

facility have tremendously promote our production capacity to a

higher level.

We provide adequate and systematic services from moulds to

injection molding production. With a group of senior technicians,

we are constantly devoted to improving quality and updating

technology.

We are determined to create the greatest values for customers with

unremitting efforts, first-class service and professional spirit.We

provide adequate and systematic services from moulds to injection

molding production.