Add to Cart

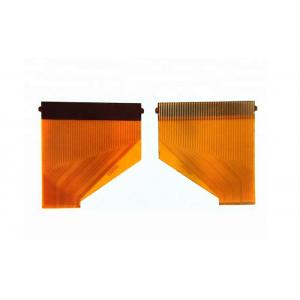

Single Sided PCB Manufacturing Process Flex PCBA Quick Pcb Prototype

We can supply:

Single layer PCBs, double layer PCBs, multilayer PCBs, high TG FR-4

PCBs, heavy copper PCBs, impedance controlled PCBs, gold finger

PCBs, plating gold PCBs, and some other PCBs according to

customers' requirements.

As your flexible circuit supplier, we will be able to build boards with line and width spacing down to 19 microns (.75 mil) and 1 mil micro vias.

FPC Capability

Rigid flex boards are extremely versatile and can be tailored to

applications across a wide range of industries. They are highly

suitable for military, aerospace, and medical devices, but they can

also be implemented towards certain commercial products.

There are several circumstances that make rigid flex PCBs as an optimal solution. In such situations, these boards are not only worth the investment, but also may be the most cost-effective choice. These include:

High-shock and high-vibration environments. Rigid flex PCBs are

highly shock resistant and can survive in high-stress environments

that would otherwise cause equipment failure.

High-precision applications where reliability is more important

than cost considerations. In situations where a cable or connector

failure would be dangerous, the more durable rigid flex PCBs are

preferable.

Flexible PCB / FPCB Applications

FPCBs are used widely in everyday technology and electronics in

addition to high-end, complex completed components. A few of the

most prominent examples of flexible circuits usage is in modern

portable electronics, devices, hard disk drives and desktop

printers.

Flexible circuits are also used extensively in other applications and industries including:

Communications,Consumer Electronics,Automotive,Medical,Industrial,Aerospace,Military,Transportation

Shenzhen Yideyi Technology Co., Ltd offer one-stop service from PCB designing, manufacturing to PCB assembling, testing and housing.

FAQ:

Q1. How to keep our product information and design file secret ?

We are willing to sign a NDA effect by customers side local law and

promising to keep customers data in high confidential level.

Q2. What file formats do you accept for production?

Gerber file: CAM350 RS274X

PCB file: Protel 99SE, P-CAD 2001 PCB

BOM: Excel (PDF,word,txt)

Q3. Please note that the following detail will speed up evaluation:

Material:

Board thickness:

Copper thickness:Surface finish:

Solder mask color:

Silkscreen color:

Q4. How can we guarantee you receive an good quality product?

For PCB, we will use Flying Probe Test, E-test etc. for it.

For PCBA, we need you to offer us a method or test fixture for the

function test.Before that, our inspectors will use microscope and

X-ray to check the IC footwelding or bad solder etc.

Q5. How to ship the PCBAs?

For small packages, we will ship the boards to you by

DHL,UPS,FEDEX,TNT. Door to door service! For mass production, we

could ship by air, by sea.

Q6. What’s the definition of PCB, PWB and FPC and what’s the

difference?

PCB is short for Printed Circuit Board;

PWB is short for Printed Wire Board, same meaning as Printed

Circuit Board;

FPC is short for Flexible Printed Board.